Your Cement to sand ratio for concrete slab images are ready. Cement to sand ratio for concrete slab are a topic that is being searched for and liked by netizens today. You can Get the Cement to sand ratio for concrete slab files here. Download all free images.

If you’re searching for cement to sand ratio for concrete slab images information related to the cement to sand ratio for concrete slab keyword, you have come to the right blog. Our website always provides you with suggestions for downloading the highest quality video and picture content, please kindly hunt and find more informative video content and images that match your interests.

Cement To Sand Ratio For Concrete Slab. 1Cement 6 bags 300 kgs. 2Fine Aggregate 1150167 689 kg. Place your concrete into your formwork. This mixing ratio is excellent for a shed slab but its also good for most concrete patios footings steps and foundation walls.

Pin On Accent Wall From pinterest.com

Pin On Accent Wall From pinterest.com

With this simple formula it is easy to estimate the amount of cement consumption required for brick masonry. Mortar 1 part cement 4 to 5 parts building sand. This tells the mixer that they need to add 1 part cement powder 2 parts sand and 3 parts aggregate in order to create the desired concrete consistency. More water cement or sand can be added if the mixture is too wet or dry. A floor screed is usually a cementitious material made from a 13 or 145 ratio of cement to sharp sand. For typical domestic use 1 cubic metre of concrete at 3500 psi 25 MPa can be readily created by mixing seven 50 kg bags of cement with 07 cubic metres of sand and 07 cubic metres of stone aggregate.

How to Calculate Quantity for Cement Sand AggregateIn This channel You can Learn about Civil Engineering Update Videos which are using generally in civ.

A concrete mix ratio is usually expressed by a set of numbers separated by colons as is the case with a 123 ratio. Ill show you the actual concrete batch plant ticket with the cement sand and aggregate break downs for the yards we used. If we mix cement sand and brick chips at 124 ratio the 28 days cube test result will come around 3000 psi. Where CementWater 048. Based on your concrete mix class and cement bag quantity multiply your volume with the corresponding values from the concrete proportion table. A concrete mix of 1 part cement.

Source: in.pinterest.com

Source: in.pinterest.com

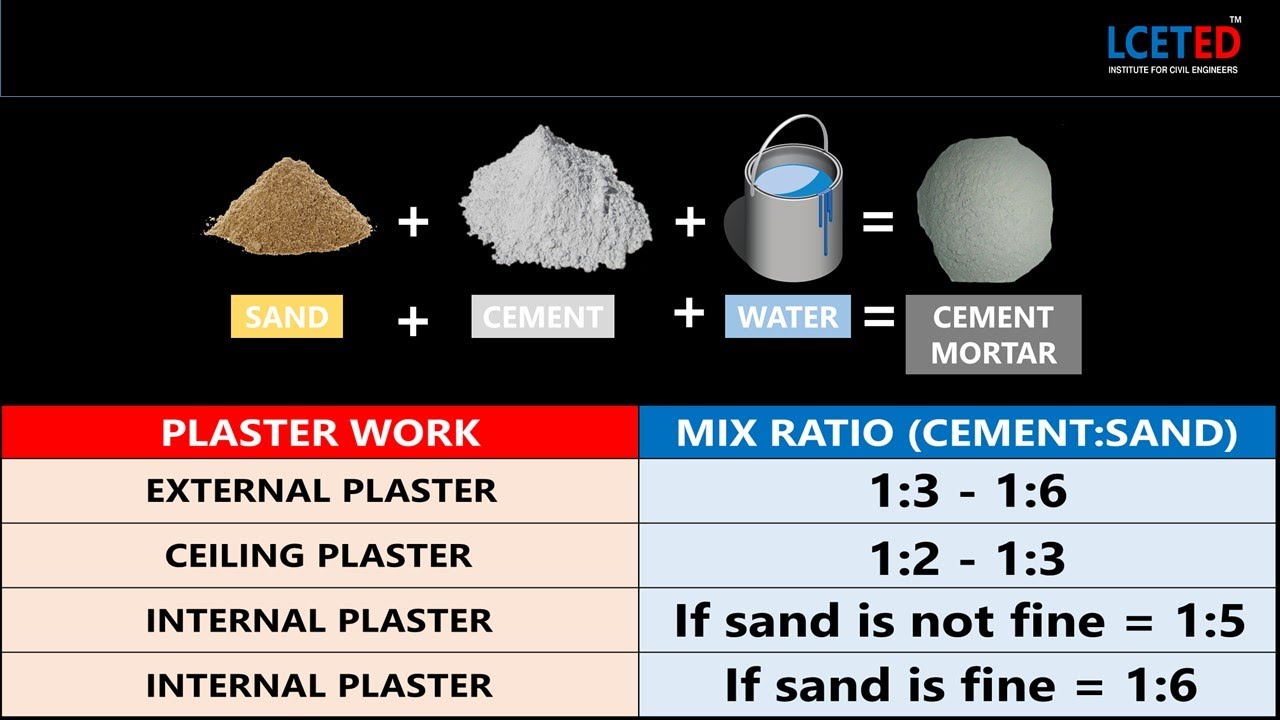

With this simple formula it is easy to estimate the amount of cement consumption required for brick masonry. 13 External wall in sever climate 14 External Wall normal conditions 14 ceiling plastering. A Premix concrete from a readymix supplier b Bagged cement sand and stone c Bagged concrete Estimating how much cement sand and stone to order The Ready Reckoner for concrete is a. With this simple formula it is easy to estimate the amount of cement consumption required for brick masonry. Select Grade of concrete M20 M25.

Source: pinterest.com

Source: pinterest.com

Grade of concrete M10 M15 M20 M25 depends on ratio of Cement Sand and Aggregate. Mortar ratio for plastering-recommended mortar ratio for plastering of planerough surface of brick wall concrete wall and ceiling are 16 14 15 13 are used respectively. More water cement or sand can be added if the mixture is too wet or dry. A concrete mix ratio is usually expressed by a set of numbers separated by colons as is the case with a 123 ratio. The cement sand ratio depends on the purpose mortar is used for.

Source: pinterest.com

Source: pinterest.com

Ill show you the actual concrete batch plant ticket with the cement sand and aggregate break downs for the yards we used. Plastering cement sand Ratio. Concrete mixed at this ratio is generally known as a C20 mix and its more than suitable for garden paths concreting fence posts shallow retaining wall foundations some extension bases. 13 External wall in sever climate 14 External Wall normal conditions 14 ceiling plastering. By increasing the cementaggregate.

Source: in.pinterest.com

Source: in.pinterest.com

If we mix cement sand and brick chips at 124 ratio the 28 days cube test result will come around 3000 psi. Answer 1 of 3. A floor screed is usually a cementitious material made from a 13 or 145 ratio of cement to sharp sand. These are the actual concrete mix ratios for 3000 3500 4000 and 4500 psi concrete that I use to pour concrete floors patios pool decks and more. A Premix concrete from a readymix supplier b Bagged cement sand and stone c Bagged concrete Estimating how much cement sand and stone to order The Ready Reckoner for concrete is a.

Source: pinterest.com

Source: pinterest.com

Based on your concrete mix class and cement bag quantity multiply your volume with the corresponding values from the concrete proportion table. Of sand cubic metres m3 cement sand stone of stone 1 2 3 16 05 08 1 25 4 13 05 08 1 3 5 11 05 09 Slab thickness in mm. There are many proprietary screeds on the market and information about these can be obtained from the manufacturer. Materials required are 7 nos. 4 parts coarse aggregate should be used for a concrete slab.

Source: pinterest.com

Source: pinterest.com

Subscribe our youtupehttpbitly2ZjMlHuvisit our social media—–for contact. Mortar Types and Uses. In terms of the ratio for concrete it depends on what strength you are trying to achieve but as a general guide a standard concrete mix would be 1 part cement to 2 parts sand to 4 parts aggregates. Typically used as the compound for joining masonry stone or ceramic units together mortar is made by combining cement lime and sand. Select DepthHeight in inches 45 inches 6 inches.

Source: pinterest.com

Source: pinterest.com

Work the concrete into awkward places and corners using a shovel or trowel. Concrete of this strength is ideal for patio slabs footpaths and steps. As a quick answer a concrete mix ratio of 1 part cement 2 parts fine aggregate sand and 4 parts course aggregate will cover most general domestic jobs. 13 External wall in sever climate 14 External Wall normal conditions 14 ceiling plastering. When we mix cement sand and stone chips at 1153 ratio the concrete strength of 28 days cube tests result comes around 3500 psi.

Source: pinterest.com

Source: pinterest.com

Like wise other concrete mix with varying proportions and materials with different physical properties the individual. 13 External wall in sever climate 14 External Wall normal conditions 14 ceiling plastering. If we mix cement sand and brick chips at 124 ratio the 28 days cube test result will come around 3000 psi. Hi Concrete without aggregate is know as mortar. 3Aggregate or 1Cement.

Source: in.pinterest.com

Source: in.pinterest.com

Mortar 1 part cement 4 to 5 parts building sand. Ill show you the actual concrete batch plant ticket with the cement sand and aggregate break downs for the yards we used. Concrete of this strength is ideal for patio slabs footpaths and steps. Select Grade of concrete M20 M25. 4Water 300055 165 kg.

Source: pinterest.com

Source: pinterest.com

Select DepthHeight in inches 45 inches 6 inches. Mortar 1 part cement 4 to 5 parts building sand. 4 Cement Sand aggregate in which one part is cement 2 part is fine aggregate or sand and 3. The cement sand ratio depends on the purpose mortar is used for. A Premix concrete from a readymix supplier b Bagged cement sand and stone c Bagged concrete Estimating how much cement sand and stone to order The Ready Reckoner for concrete is a.

Source: pinterest.com

Source: pinterest.com

Work the concrete into awkward places and corners using a shovel or trowel. If you are looking for construction cost calculator then have a look on it here. Work the concrete into awkward places and corners using a shovel or trowel. Place your concrete into your formwork. A Premix concrete from a readymix supplier b Bagged cement sand and stone c Bagged concrete Estimating how much cement sand and stone to order The Ready Reckoner for concrete is a.

Source: pinterest.com

Source: pinterest.com

The cement sand ratio depends on the purpose mortar is used for. Concrete Mix Ratio Using Ballast. More water cement or sand can be added if the mixture is too wet or dry. 2Fine Aggregate 1150167 689 kg. For foundations a mix of 1 part cement to 3.

Source: pinterest.com

Source: pinterest.com

4Water 300055 165 kg. 13 ratio is recommended for RCC surfac. 2Fine Aggregate 1150167 689 kg. Subscribe our youtupehttpbitly2ZjMlHuvisit our social media—–for contact. Select DepthHeight in inches 45 inches 6 inches.

Source: pinterest.com

Source: pinterest.com

More water cement or sand can be added if the mixture is too wet or dry. Concrete 1 part cement 2 parts concreting sand and 3 parts 20 millimeter aggregate. Mortar 1 part cement 4 to 5 parts building sand. Water is not included in these ratios though because it can vary more. Concrete Mix Ratio Using Ballast.

Source: pinterest.com

Source: pinterest.com

2Fine Aggregate 1150167 689 kg. Concrete of this strength is ideal for patio slabs footpaths and steps. More water cement or sand can be added if the mixture is too wet or dry. If you are looking for construction cost calculator then have a look on it here. A concrete mix of 1 part cement.

Source: pinterest.com

Source: pinterest.com

Of 50 kg bag of cement 042 m 3 of sand and 083 m 3 of stone aggregate. A Premix concrete from a readymix supplier b Bagged cement sand and stone c Bagged concrete Estimating how much cement sand and stone to order The Ready Reckoner for concrete is a. The most common ratio referred here in Bangladesh for column concrete 1153 and for slab 124. Ill show you the actual concrete batch plant ticket with the cement sand and aggregate break downs for the yards we used. This tells the mixer that they need to add 1 part cement powder 2 parts sand and 3 parts aggregate in order to create the desired concrete consistency.

Source: pinterest.com

Source: pinterest.com

For typical domestic use 1 cubic metre of concrete at 3500 psi 25 MPa can be readily created by mixing seven 50 kg bags of cement with 07 cubic metres of sand and 07 cubic metres of stone aggregate. Of sand cubic metres m3 cement sand stone of stone 1 2 3 16 05 08 1 25 4 13 05 08 1 3 5 11 05 09 Slab thickness in mm. 4 Cement Sand aggregate in which one part is cement 2 part is fine aggregate or sand and 3. Mortar 1 part cement 4 to 5 parts building sand. Compute for the quantity of 40kg cement bags sand and gravel needed for a class A mixture slab that is 3 meters long 2 meters wide and 0150 meters thick.

Source: pinterest.com

Source: pinterest.com

There are many proprietary screeds on the market and information about these can be obtained from the manufacturer. Typically used as the compound for joining masonry stone or ceramic units together mortar is made by combining cement lime and sand. Work the concrete into awkward places and corners using a shovel or trowel. Hi Concrete without aggregate is know as mortar. The most common ratio referred here in Bangladesh for column concrete 1153 and for slab 124.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title cement to sand ratio for concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.