Your Concrete slump for slab on grade images are available. Concrete slump for slab on grade are a topic that is being searched for and liked by netizens today. You can Get the Concrete slump for slab on grade files here. Download all free vectors.

If you’re looking for concrete slump for slab on grade pictures information linked to the concrete slump for slab on grade interest, you have come to the ideal site. Our site always gives you hints for downloading the highest quality video and image content, please kindly hunt and find more informative video articles and images that match your interests.

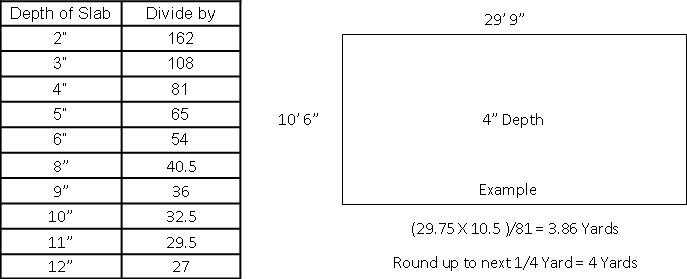

Concrete Slump For Slab On Grade. Recommended slumps for various types of construction Types of construction Maximum Slump in. 4 Slab concrete placed in ambient temperatures at 30C or above shall contain an. The strength will fall around 30 Nmm 2 4500 psi. BASIS OF FLOOR SLAB ON GRADE DESIGN 2-1.

As Simple As 1 2 3 Concrete Construction Magazine From concreteconstruction.net

As Simple As 1 2 3 Concrete Construction Magazine From concreteconstruction.net

They imply that if slump is low then almost everything possible has been done to minimize shrinkage. A large proportion by weight of flyash should be made in consideration which reduces shrinkage but generates a slower strength gain. However no matter how basic or complex the floor is the construction method is similar and includes. Floor slabs can range from a simple residential basement slab to a heavy-duty industrial floor. S1 slumps are most likely to be used for kerb and pipework bedding because its quite a dry concrete mix. I have the following.

My question is about my slab on grade mix design.

Columns and beams are congested and hence need more flow 120mm-20mm slump should be enough. If you want more slump it is always safest for the concrete to adjust slump at the plant. We should use a low slump concrete in order to reduce the shrinkage. This is sometimes referred to as semi-dry. 3 Slab concrete placed in ambient temperatures less than 10C shall contain an approved compatible accelerator at the manufactures required dosage. For residential slabs and footings in the absence of any specification by the customer a slump of 100 mm will be supplied.

The commonly specified 28-day compressive strength has been increased. C o m p ressive strength is overe m p h a - s i z e d. The strength will fall around 30 Nmm 2 4500 psi. Surprisingly the recommended slumps for concrete were quite liberal as follows. The concrete are often used to improve durability and workability.

Source: civilconcept.com

Source: civilconcept.com

Between 3500 to 5000 psi on suspended slabs beams and girders. S2 slumps are used for simple strip footings and cast in-situ hard-standing slabs or when using a wheel barrow to move the concrete. C o m p ressive strength is overe m p h a - s i z e d. This is the typical SOG design we use for interior slabs. This is sometimes referred to as semi-dry.

Source: carrollsbuildingmaterials.com

Source: carrollsbuildingmaterials.com

For residential slabs and footings in the absence of any specification by the customer a slump of 100 mm will be supplied. A wc ratio of 0040 and 5-12 sack specification with 900 to 1000 kg 2000 to 2200 lb of aggregate and six per cent air with welded wire. The use of fully compacted low-slump concrete followed by the floating and trowelling operations at the correct times will avoid the production of an excessively thick layer of laitance and result in a durable pavement surface. When non-reinforced concrete is used different strengths will be required. This is the typical SOG design we use for interior slabs.

Source: in.pinterest.com

Source: in.pinterest.com

A slab with a thick layer of surface laitance will wear rapidly possibly craze and dust badly. A 4 inch slump the measure of the distance a wet concrete cone will fall is typical. Thermal expansion and contraction of the concrete The structural design of a concrete floor slab on grade is primarily controlled by the stresses caused by moving live loads and in some cases the stationary loads. Superplasticisers or high range water reducers can greatly increase slump with a relatively small dose. The concrete topping used should have a maximum slump of 75 mm.

Source: researchgate.net

Source: researchgate.net

Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab. Slabs could have less flow and hence 100mm-20mm slump should be enough. S1 slumps are most likely to be used for kerb and pipework bedding because its quite a dry concrete mix. We should use a low slump concrete in order to reduce the shrinkage. Concrete for floor slabs on grade.

Source: slideplayer.com

Source: slideplayer.com

Information not presented in this guide includes above-grade concrete walls deep foundation systems such as piles drilled piers or caissons free-standing retaining walls 4 ft 12 m post-tensioned slabs-on-ground and elevated concrete slabs. 52Slabs-on-ground 521 Required design elementsFollowing are the minimum items that should be addressed in the construction. The concrete are often used to improve durability and workability. Unless otherwise permitted or specified the concrete should be proportioned and produced to have a slump of 4 inches or less if its to be consolidated by vibration. Columns and beams are congested and hence need more flow 120mm-20mm slump should be enough.

Source: researchgate.net

Source: researchgate.net

Floor slabs can range from a simple residential basement slab to a heavy-duty industrial floor. Shrinkage testing should be every bit as important as com-pressive strength testing for enclosed slabs on grade. Typically reinforced concrete ranging between 3500 to 4000 psi is used on footing and slabs on grade. 30MPa for light duty 40 MPa for medium duty and 50 MPa for heavy duty. Slump Slump is a measure of the consistency of the concrete.

Source: concreteconstruction.net

Source: concreteconstruction.net

The concrete topping used should have a maximum slump of 75 mm. Stresses in floor slabs on grade resulting from vehicular loads are a function of floor. Max WC 040. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab. A good slump for most flatwork placed by hand.

Source: in.pinterest.com

Source: in.pinterest.com

This is the typical SOG design we use for interior slabs. My question is about my slab on grade mix design. For slabs struck off with mechanical equipment. A good slump for most flatwork placed by hand. And walls and columns normally require between 3000 to 5000 psi.

Source: wikiwand.com

Source: wikiwand.com

For residential slabs and footings in the absence of any specification by the customer a slump of 100 mm will be supplied. Use appropriate cement contents in the range of 305 to 335. A slab with a thick layer of surface laitance will wear rapidly possibly craze and dust badly. Even high slump caused by admixtures can be detrimental as the paste content and shrinkage of the upper portion of the slab can be greater than the lower portion of the slab leading to increased warping. 4 Slab concrete placed in ambient temperatures at 30C or above shall contain an.

Air content 55 - 1. We should use a low slump concrete in order to reduce the shrinkage. For residential slabs and footings in the absence of any specification by the customer a slump of 100 mm will be supplied. A wc ratio of 0040 and 5-12 sack specification with 900 to 1000 kg 2000 to 2200 lb of aggregate and six per cent air with welded wire. Between 3500 to 5000 psi on suspended slabs beams and girders.

The concrete are often used to improve durability and workability. S1 slumps are most likely to be used for kerb and pipework bedding because its quite a dry concrete mix. Stresses in floor slabs on grade resulting from vehicular loads are a function of floor. However no matter how basic or complex the floor is the construction method is similar and includes. C o m p ressive strength is overe m p h a - s i z e d.

For slabs struck off with mechanical equipment. The concrete are often used to improve durability and workability. Two to four inches. This is sometimes referred to as semi-dry. Information on the use of lightweight concrete is not covered in this guide.

Source: concreteconstruction.net

Source: concreteconstruction.net

C o m p ressive strength is overe m p h a - s i z e d. This is sometimes referred to as semi-dry. 3 Slab concrete placed in ambient temperatures less than 10C shall contain an approved compatible accelerator at the manufactures required dosage. A wc ratio of 0040 and 5-12 sack specification with 900 to 1000 kg 2000 to 2200 lb of aggregate and six per cent air with welded wire. Do not use concrete with a high slump excessively high air content or excess fines.

![]() Source: civiconcepts.com

Source: civiconcepts.com

The use of fully compacted low-slump concrete followed by the floating and trowelling operations at the correct times will avoid the production of an excessively thick layer of laitance and result in a durable pavement surface. Information on the use of lightweight concrete is not covered in this guide. The concrete are often used to improve durability and workability. This is the typical SOG design we use for interior slabs. If you want more slump it is always safest for the concrete to adjust slump at the plant.

Source: pinterest.com

Source: pinterest.com

I have the following. This is sometimes referred to as semi-dry. If its consolidated any. A good slump for most flatwork placed by hand. Preparing the sub-grade and sub-base placing the reinforcement and concrete and finishing and curing the slab.

A wc ratio of 0045 and 5-12 sack content with 900-kg 2000-lb of large aggregate with welded wire reinforcement is a good standby mix design for an interior slab-on-grade. Surprisingly the recommended slumps for concrete were quite liberal as follows. 100-mm-thick 4-in unreinforced concrete slabs on grade and at about 6-m 20-ft intervals in 200-mm-thick 8-in slabs. Stresses in floor slabs on grade resulting from vehicular loads are a function of floor. 4 Slab concrete placed in ambient temperatures at 30C or above shall contain an.

For concrete floor construction are found in ACI 360R for slabs-on-ground ACI 223R for shrinkage-compensating concrete floors and ACI 4211R and 4212R for suspended floors. The use of fully compacted low-slump concrete followed by the floating and trowelling operations at the correct times will avoid the production of an excessively thick layer of laitance and result in a durable pavement surface. 3 Slab concrete placed in ambient temperatures less than 10C shall contain an approved compatible accelerator at the manufactures required dosage. C o m p ressive strength is overe m p h a - s i z e d. Concrete for floor slabs on grade.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title concrete slump for slab on grade by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.