Your Concrete wall forming methods images are available. Concrete wall forming methods are a topic that is being searched for and liked by netizens today. You can Download the Concrete wall forming methods files here. Download all free photos and vectors.

If you’re searching for concrete wall forming methods pictures information connected with to the concrete wall forming methods topic, you have come to the right blog. Our site frequently provides you with suggestions for downloading the maximum quality video and image content, please kindly search and locate more informative video content and graphics that fit your interests.

Concrete Wall Forming Methods. Securely attach the triangu-. A full footing is not required for some applications with the Precise Fence Forms. The process is designed for a small crew and offers an alternative to a method described by a previous author on the same subject. These forms are often made of materials such as melamine laminated board or acrylic glass screw mounted to a large board.

Wall Forms Are Constructed In Various Shapes Heights And Thicknesses Ppt Download From slideplayer.com

Wall Forms Are Constructed In Various Shapes Heights And Thicknesses Ppt Download From slideplayer.com

Selecting prefabricated form components. The rate of dragging slipping the formwork will vary and it will depend upon the temperature and strength development of concrete to withstand without the support of formwork. Horizontal and vertical slipforming jump forming and cantilever forming flying forms lift slab tunnel forming traveling forms tilt-up leave-in-place forms shotcreting preplaced aggregate concrete tremie concrete slurry wall construction. These are either nailed or screwed together to the desired mold or formwork shape. A mold form is placed upon on a surface at a construction site. Building forms stick by stick can save on labor and materials.

Wooden form is the basic and the most conventional type of concrete form.

Selecting prefabricated form components. The rate of dragging slipping the formwork will vary and it will depend upon the temperature and strength development of concrete to withstand without the support of formwork. This type of one-sided form can be readily ganged and moved by crane. WTFs innovative design long lasting products ease of setup and speed of construction assure that you wont be confined by inferior or restrictive products. The forms are shaped and rebar cut to match final designs. 54 When erecting forms for battered walls allowance must be provided for proper anchorage to resist resulting uplift forces.

Source: slideplayer.com

Source: slideplayer.com

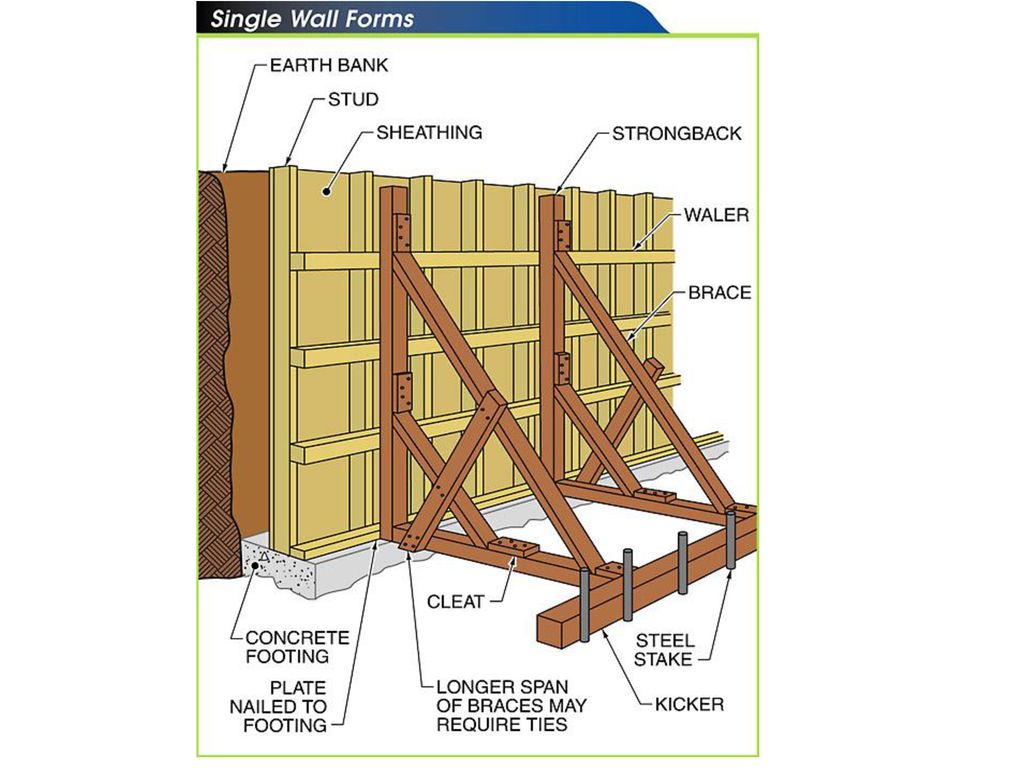

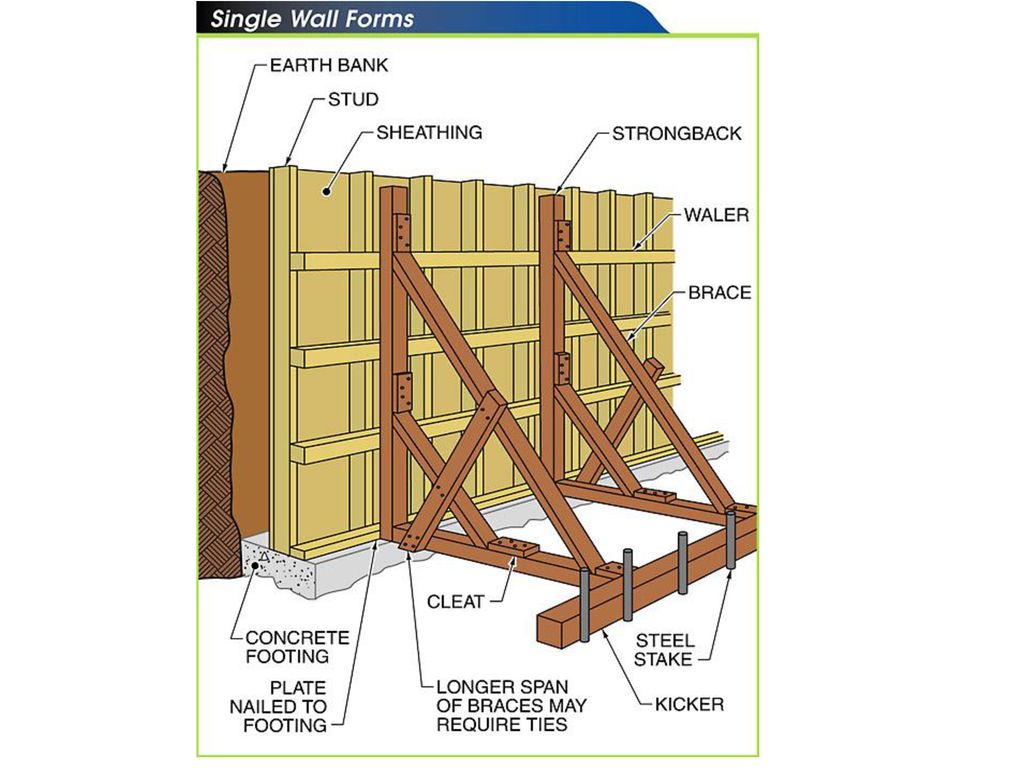

The forms are shaped and rebar cut to match final designs. It is employed mainly for concrete casting that does not exceed 6 inches of height. Attach vertical wales or strongbacks to a form panel. This article gives brief descriptions of some of the most usual methods of constructing with concrete including. The method comprises use of connectors for temporarily connecting two forms in rearward abutment to make a form unit placing form units on a foundation into adjacent interfitting engagement in a.

Source: nzdl.org

Source: nzdl.org

Plywood forms are typically used where unique wall shapes sizes and embedment. Ensure that all anchorages and bracing are installed per layout drawings. This article gives brief descriptions of some of the most usual methods of constructing with concrete including. The method comprises use of connectors for temporarily connecting two forms in rearward abutment to make a form unit placing form units on a foundation into adjacent interfitting engagement in a. The forms are shaped and rebar cut to match final designs.

Source: youtube.com

Source: youtube.com

Plywood forms are typically used where unique wall shapes sizes and embedment. So if your wall is. Ensure that all anchorages and bracing are installed per layout drawings. Forms and adaptable to masonry walls. A method of constructing a concrete wall.

Source: youtube.com

Source: youtube.com

54 When erecting forms for battered walls allowance must be provided for proper anchorage to resist resulting uplift forces. Wooden form is the basic and the most conventional type of concrete form. Many consider aluminum and steel wall forming systems to be more productive efficient and even economical than wood forming. Building forms stick by stick can save on labor and materials. The forms are shaped and rebar cut to match final designs.

Source: wikihow.com

Source: wikihow.com

Drive a nail into the concrete here. Simply pour footings where the columns are located and tie the rebar into place. A support structure is placed into the mold form and concrete is. These panels are created at the work site using wood forms rebar and concrete. Measure out from that nail to where the other face of your wall will be and place another nail.

Source: builderbill-diy-help.com

Source: builderbill-diy-help.com

Horizontal and vertical slipforming jump forming and cantilever forming flying forms lift slab tunnel forming traveling forms tilt-up leave-in-place forms shotcreting preplaced aggregate concrete tremie concrete slurry wall construction. A mold form is placed upon on a surface at a construction site. 5 Align the forms. Forms and adaptable to masonry walls. A method of constructing a concrete wall.

Source: slideplayer.com

Source: slideplayer.com

A support structure is placed into the mold form and concrete is. A tunnel form is a box-sized steel fabricated form that allows the wall and the slab to be cast in a single operation. 55 Layouts must be prepared by a qualified formwork designer for all one-sided and cantilevered wall forming applications. Measure from the edge of your concrete footing to the point where the outside face of your wall will be. This type of one-sided form can be readily ganged and moved by crane.

Source: nzdl.org

Source: nzdl.org

8 Strip the form. Selecting prefabricated form components. Attach vertical wales or strongbacks to a form panel. The system creates an efficient concrete wall slab load-bearing structure for use in a wide variety of applications. Wooden form is the basic and the most conventional type of concrete form.

Source: fantasticeng.com

Source: fantasticeng.com

Attach vertical wales or strongbacks to a form panel. Measure out from that nail to where the other face of your wall will be and place another nail. Concrete wall forms are typically made of plywood aluminum or steel. This article gives brief descriptions of some of the most usual methods of constructing with concrete including. 10 Reconfigure form if needed.

Source: researchgate.net

Source: researchgate.net

Wooden form is the basic and the most conventional type of concrete form. The rate of dragging slipping the formwork will vary and it will depend upon the temperature and strength development of concrete to withstand without the support of formwork. 54 When erecting forms for battered walls allowance must be provided for proper anchorage to resist resulting uplift forces. Wooden form is the basic and the most conventional type of concrete form. Ensure that all anchorages and bracing are installed per layout drawings.

Source: wikihow.com

Source: wikihow.com

Simply pour footings where the columns are located and tie the rebar into place. Measure out from that nail to where the other face of your wall will be and place another nail. Building forms stick by stick can save on labor and materials. Plywood forms are typically used where unique wall shapes sizes and embedment. Wooden form is the basic and the most conventional type of concrete form.

Source: slideplayer.com

Source: slideplayer.com

4 Install ties. 2 Rebar placement 3 Set the other wall side of the form. 10 Reconfigure form if needed. These are either nailed or screwed together to the desired mold or formwork shape. Plywood forms are typically used where unique wall shapes sizes and embedment.

Source: nzdl.org

Source: nzdl.org

Attach vertical wales or strongbacks to a form panel. It is employed mainly for concrete casting that does not exceed 6 inches of height. These forms are often made of materials such as melamine laminated board or acrylic glass screw mounted to a large board. Simply pour footings where the columns are located and tie the rebar into place. Measure out from that nail to where the other face of your wall will be and place another nail.

Source: nzdl.org

Source: nzdl.org

It is employed mainly for concrete casting that does not exceed 6 inches of height. Measure out from that nail to where the other face of your wall will be and place another nail. Drive a nail into the concrete here. Next concrete is poured into the forms and finished. Simply pour footings where the columns are located and tie the rebar into place.

Source: formingamerica.com

Source: formingamerica.com

Forms and adaptable to masonry walls. Horizontal and vertical slipforming jump forming and cantilever forming flying forms lift slab tunnel forming traveling forms tilt-up leave-in-place forms shotcreting preplaced aggregate concrete tremie concrete slurry wall construction. So if your wall is. It is employed mainly for concrete casting that does not exceed 6 inches of height. Ensure that all anchorages and bracing are installed per layout drawings.

Source: researchgate.net

Source: researchgate.net

Measure from the edge of your concrete footing to the point where the outside face of your wall will be. Fence Forms The Precise Forms Fence Forming System is the ultimate solution to creating cast in place concrete fences. A mold form is placed upon on a surface at a construction site. Wall forms are held together with the same type of slotted flat metal ties used in reusable concrete forms. Horizontal and vertical slipforming jump forming and cantilever forming flying forms lift slab tunnel forming traveling forms tilt-up leave-in-place forms shotcreting preplaced aggregate concrete tremie concrete slurry wall construction.

Source: youtube.com

Source: youtube.com

A tunnel form is a box-sized steel fabricated form that allows the wall and the slab to be cast in a single operation. A method of constructing a concrete wall. Ensure that all anchorages and bracing are installed per layout drawings. Tilt-Up construction features series of concrete panels tilted up into place to form a buildings exterior wall. Simply pour footings where the columns are located and tie the rebar into place.

Source: slideplayer.com

Source: slideplayer.com

Wall forms are held together with the same type of slotted flat metal ties used in reusable concrete forms. 2 Rebar placement 3 Set the other wall side of the form. WTFs innovative design long lasting products ease of setup and speed of construction assure that you wont be confined by inferior or restrictive products. Drive a nail into the concrete here. Then add a hori-zontal and diagonal wale to the vertical wale to form tri-angular waler frames that re-sist the pressure of fresh con-crete Figure 2.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title concrete wall forming methods by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.