Your Construction joint forming concrete slabs images are available. Construction joint forming concrete slabs are a topic that is being searched for and liked by netizens now. You can Get the Construction joint forming concrete slabs files here. Download all free photos and vectors.

If you’re looking for construction joint forming concrete slabs images information related to the construction joint forming concrete slabs topic, you have come to the right site. Our website frequently gives you suggestions for viewing the maximum quality video and image content, please kindly hunt and find more informative video content and images that match your interests.

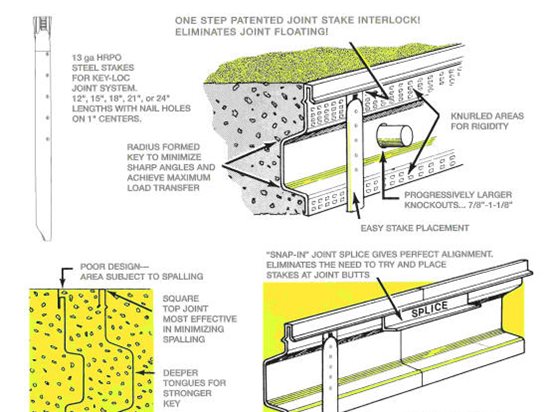

Construction Joint Forming Concrete Slabs. A plurality of stakes adapted to be vertically set in transversely aligned relationship with the upper ends thereof disposed uniformly below grade level said stakes each having an upwardly facing strip supporting ledge. Groover tools for forming joints. The soils or granular fill supporting the slab in service must be either undisturbed soil or well compacted. Load transfer is required principally for wheel loads but also stack loading over joint.

Joints In Concrete Slabs On A Grade What Why How Nevada Ready Mix From nevadareadymix.com

Joints In Concrete Slabs On A Grade What Why How Nevada Ready Mix From nevadareadymix.com

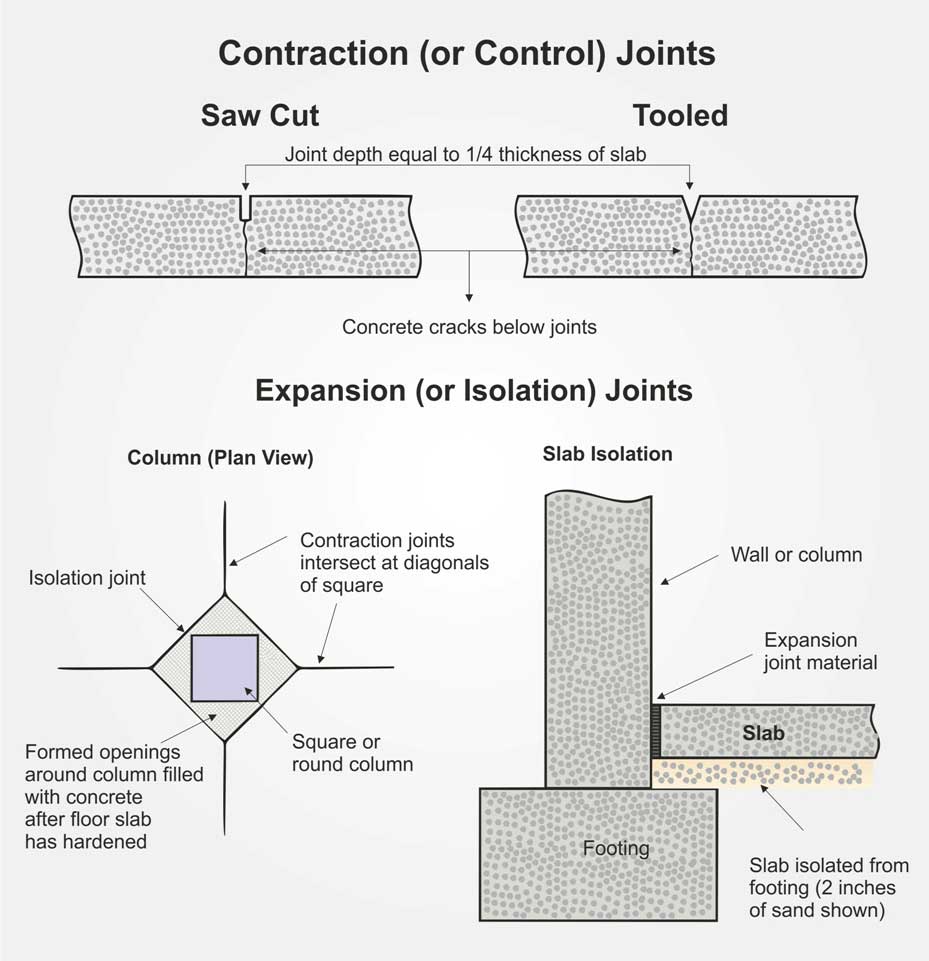

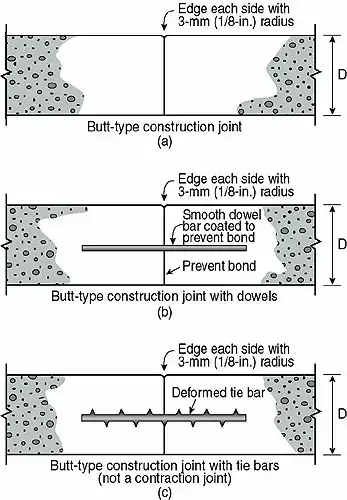

A construction joint is a joint between slabs that results when concrete is placed at different times. Joints in concrete slabs can be created by forming sawing tooling placement of joint formers. Using Dowels for slabs below 150mm thickness. Groover tools for forming joints. Concrete slabs-on-ground have consistently performed very well when the following considerations are addressed. The use of skewed joints to reduce impact at the joint should be considered.

Concrete expands when it dries out and strains under pressure so expansion joints are required in order to prevent cracks from forming in the slab.

Concrete expansion joints are either vertical or horizontal. We create a weakened line across the slab. The use of skewed joints to reduce impact at the joint should be considered. Concrete expansion joints are either vertical or horizontal. Joints in construction are designed to eliminate weakened planes in concrete allow cracks to occur at the proper location because of dimensional changes. Concrete is not a ductile materialit doesnt stretch or bend without.

Source: theconstructor.org

Source: theconstructor.org

US3143783A US240272A US24027262A US3143783A US 3143783 A US3143783 A US 3143783A US 240272 A US240272 A US 240272A US 24027262 A US24027262 A US 24027262A US 3143783 A US3143783 A US 3143783A Authority US United States Prior art keywords strip stakes concrete planar key Prior art date 1962-11-27 Legal status The legal. If constru c - tion joints are located where no movement is wanted tie bars or welded wire fabric can be used to hold the adja-cent slabs together. When concreting is interrupted long enough for the placed concrete to harden the construction documents should provide a detail to address this unplanned event ACI Committee 360 2010 Control Joint. They can be made to function as isolation joints by lining the bulkhead with a pre f o r med sheet material or as control joints by using keyed bulkheads. Joints in concrete slabs can be created by forming sawing tooling placement of joint formers.

Source: buildmagazine.org.nz

Source: buildmagazine.org.nz

This type of joint can be further broken down into transverse and longitudinal construction. A construction joint is a joint between slabs that results when concrete is placed at different times. Concrete slab joints are created by forming tooling sawing and putting in joint formers. Use an isolation joint between concrete slabs of different shapes or thicknesses and around all columns footings and peripheries of buildings. As a result for a 4-inch thick concrete slab expansion joints should be spaced no more than 8 to 12 feet apart.

![]() Source: civiconcepts.com

Source: civiconcepts.com

Using Dowels for slabs below 150mm thickness. Place joints at the inside point of V-shaped rustication. They can be made to function as isolation joints by lining the bulkhead with a pre f o r med sheet material or as control joints by using keyed bulkheads. Concrete slab joints are created by forming tooling sawing and putting in joint formers. This type of joint can be further broken down into transverse and longitudinal construction.

Source: m.youtube.com

Source: m.youtube.com

A construction joint is a joint between slabs that results when concrete is placed at different times. Concrete expansion joints are either vertical or horizontal. The use of skewed joints to reduce impact at the joint should be considered. Typical details for a construction joint in a concrete pavement or industrial floor on grade are shown in Figure 2. They can be made to function as isolation joints by lining the bulkhead with a pre f o r med sheet material or as control joints by using keyed bulkheads.

![]() Source: civiconcepts.com

Source: civiconcepts.com

Both isolation and construction joints are formed before the concrete is poured. The joints illustrated are formed after construction. In addition contraction joints should be placed to produce panels that are as square as possible and never exceeding a length to width ratio of. Vertical joints are made by cutting slots into the side of a concrete. Concrete slab joints are created by forming tooling sawing and putting in joint formers.

Source: theconstructor.org

Source: theconstructor.org

Typical details for a construction joint in a concrete pavement or industrial floor on grade are shown in Figure 2. Concrete expansion joints are either vertical or horizontal. Vertical joints are made by cutting slots into the side of a concrete. They can be made to function as isolation joints by lining the bulkhead with a pre f o r med sheet material or as control joints by using keyed bulkheads. Joints such as isolation expansion are used to isolate structural elements such as walls footings columns driveways patios from.

Source: concretenz.org.nz

Source: concretenz.org.nz

Different types of concrete joints are discussed below. Page 2Joints in Concrete Buildings Top of floor Beam soffit Scabble and clean laitence off surface prior to placing beam reinforcement Longitudinal. Often in reinforced concrete a conscious effort is. When concreting is interrupted long enough for the placed concrete to harden the construction documents should provide a detail to address this unplanned event ACI Committee 360 2010 Control Joint. US3143783A US240272A US24027262A US3143783A US 3143783 A US3143783 A US 3143783A US 240272 A US240272 A US 240272A US 24027262 A US24027262 A US 24027262A US 3143783 A US3143783 A US 3143783A Authority US United States Prior art keywords strip stakes concrete planar key Prior art date 1962-11-27 Legal status The legal.

Source: m.youtube.com

Source: m.youtube.com

Concrete is not a ductile materialit doesnt stretch or bend without. What is claimed is. When concreting is interrupted long enough for the placed concrete to harden the construction documents should provide a detail to address this unplanned event ACI Committee 360 2010 Control Joint. This joint can be used where limited load transfer is required where unreinforced slabs are used with restricted bay sizes. In addition contraction joints should be placed to produce panels that are as square as possible and never exceeding a length to width ratio of.

Source: engineersdaily.com

Source: engineersdaily.com

Typical details for a construction joint in a concrete pavement or industrial floor on grade are shown in Figure 2. In addition contraction joints should be placed to produce panels that are as square as possible and never exceeding a length to width ratio of. Place joints at the inside point of V-shaped rustication. In slabs they may be designed to permit movement andor to transfer load. These are joints that are placed at the end of a days work.

![]() Source: civiconcepts.com

Source: civiconcepts.com

Page 2Joints in Concrete Buildings Top of floor Beam soffit Scabble and clean laitence off surface prior to placing beam reinforcement Longitudinal. Load transfer is required principally for wheel loads but also stack loading over joint. O ACI Construction joints are placed in a slab to define the extent of the individual placements generally in conformity with a predetermined joint layout. A plurality of stakes adapted to be vertically set in transversely aligned relationship with the upper ends thereof disposed uniformly below grade level said stakes each having an upwardly facing strip supporting ledge. Often in reinforced concrete a conscious effort is.

How to form joints. Joints such as isolation expansion are used to isolate structural elements such as walls footings columns driveways patios from. Vertical joints are made by cutting slots into the side of a concrete. The slab reinforcement is carried through the joint and extra tie bars are inserted to hold the two sides together. Concrete slabs-on-ground have consistently performed very well when the following considerations are addressed.

Source: concretenetwork.com

Source: concretenetwork.com

These are joints that are placed at the end of a days work. In addition contraction joints should be placed to produce panels that are as square as possible and never exceeding a length to width ratio of. These are joints that are placed at the end of a days work. How to form joints. As a result for a 4-inch thick concrete slab expansion joints should be spaced no more than 8 to 12 feet apart.

Source: continuingeducation.bnpmedia.com

Source: continuingeducation.bnpmedia.com

When concreting is interrupted long enough for the placed concrete to harden the construction documents should provide a detail to address this unplanned event ACI Committee 360 2010 Control Joint. An improved strip and supporting stake construction for forming a key joint between adjacent concrete slabs said construction comprising. They can also be formed up joints. We create a weakened line across the slab. In slabs they may be designed to permit movement andor to transfer load.

Source: pavementinteractive.org

Source: pavementinteractive.org

They may be designed to permit movement andor to transfer load. They can also be formed up joints. Often in reinforced concrete a conscious effort is. To place the joints mark the exact location of all joints on plans and indicate the means of forming them. Construction joints occur where two successive placements of concrete meet.

Source: constrofacilitator.com

Source: constrofacilitator.com

This type of joint can be further broken down into transverse and longitudinal construction. A construction joint is a joint between slabs that results when concrete is placed at different times. Both isolation and construction joints are formed before the concrete is poured. They can be made to function as isolation joints by lining the bulkhead with a pre f o r med sheet material or as control joints by using keyed bulkheads. In addition contraction joints should be placed to produce panels that are as square as possible and never exceeding a length to width ratio of.

Source: civiljungle.com

Source: civiljungle.com

US3143783A US240272A US24027262A US3143783A US 3143783 A US3143783 A US 3143783A US 240272 A US240272 A US 240272A US 24027262 A US24027262 A US 24027262A US 3143783 A US3143783 A US 3143783A Authority US United States Prior art keywords strip stakes concrete planar key Prior art date 1962-11-27 Legal status The legal. The soils or granular fill supporting the slab in service must be either undisturbed soil or well compacted. A plurality of stakes adapted to be vertically set in transversely aligned relationship with the upper ends thereof disposed uniformly below grade level said stakes each having an upwardly facing strip supporting ledge. O ACI Construction joints are placed in a slab to define the extent of the individual placements generally in conformity with a predetermined joint layout. They can also be formed up joints.

Source: everything-about-concrete.com

Source: everything-about-concrete.com

Concrete expansion joints are either vertical or horizontal. A plurality of stakes adapted to be vertically set in transversely aligned relationship with the upper ends thereof disposed uniformly below grade level said stakes each having an upwardly facing strip supporting ledge. Joints in construction are designed to eliminate weakened planes in concrete allow cracks to occur at the proper location because of dimensional changes. What is claimed is. Use an isolation joint between concrete slabs of different shapes or thicknesses and around all columns footings and peripheries of buildings.

Source: nevadareadymix.com

Source: nevadareadymix.com

Contraction joints or control joints are placed in the fresh concrete before it has a chance to create its own jointsalso known as cracks. Joints in concrete can serve both to prevent cracking and as a decorative element. What a contraction joint really is in the end is a crack in the slab that we force to follow a line of our own choosing. They can be made to function as isolation joints by lining the bulkhead with a pre f o r med sheet material or as control joints by using keyed bulkheads. Load transfer is required principally for wheel loads but also stack loading over joint.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title construction joint forming concrete slabs by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.