Your How to protect copper pipe in concrete slab images are available. How to protect copper pipe in concrete slab are a topic that is being searched for and liked by netizens now. You can Download the How to protect copper pipe in concrete slab files here. Download all royalty-free photos and vectors.

If you’re looking for how to protect copper pipe in concrete slab pictures information connected with to the how to protect copper pipe in concrete slab topic, you have pay a visit to the right blog. Our website frequently gives you suggestions for downloading the maximum quality video and image content, please kindly surf and locate more informative video articles and graphics that fit your interests.

How To Protect Copper Pipe In Concrete Slab. If you have foam pipe insulation you can use that instead of FG. Unlike basement-type or crawlspace-type foundations a slab foundation makes accessing utilities difficult because the utilities will be encased in concrete. 15mm copper pipes will need to move as they expand contract with the heat produced. Any water copper pipework to be burried in a concrete slab should always ve protected as to not react with the cement whilst it is going off.

3 Benefits Of Hiring A Waterproofing Contractor Drain Repair Slab Leak Contractors From pinterest.com

3 Benefits Of Hiring A Waterproofing Contractor Drain Repair Slab Leak Contractors From pinterest.com

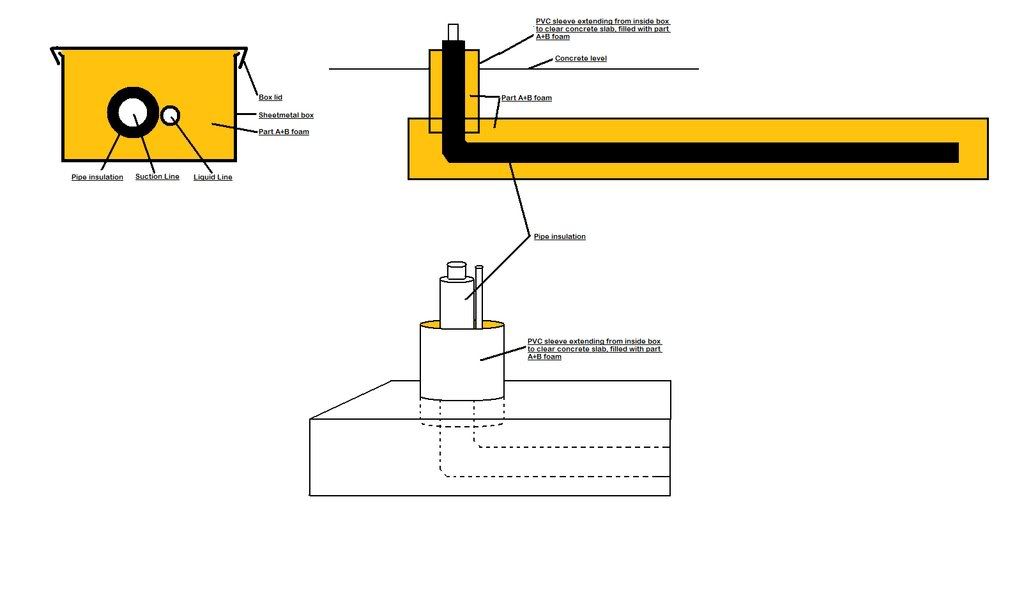

Ive also been told to wrap protruding copper pipes with tar paper before embedding them in concrete. If you do not have soil between the pipe and slab bridging the slab will protect the top of the pipe but increase the lateral load on the pipe. Please refer to your local plumbing code for specific requirements regarding the protection of pipes and tubes passing through concrete and masonry floors and walls. Break the slab cap them off and put some sort of access box and cover or 3. In years gone by the material of choice would have been denzo tape but these days most engineers use insulation tape and pipe lagging with cable ties as this will protect the copped from being corroded by the cement. How to repair copper pipes using a sleeve step 1.

If you can find the point of entry and follow it to the meter use a placement for your sump pit far from this assumed line.

The rebar will show on the detector and mask the copper. Wrap hessian sleeving around all of the pipes ensuring theyre covered 2. An expectation that may not be realized when this out-of-site out-of-mind philosophy extends to. In cases where PEX pipe penetrates a concrete slab it must be protected with a nonmetallic sleeve at the penetration point. Get Quotes From Pros. 15mm copper pipes will need to move as they expand contract with the heat produced.

Source: diynot.com

Source: diynot.com

I know this sounds nuts but it helps spot the leak. Stuff fiberglass in the void and caulk with Neutral cure Silicone sealant tool concave with spatula. One of the pipes supply hot water and has a visible dent in it. Im not convinced this is enough and so I was planning to ask he does the following 1. The normal practice that Im familiar with is to install the piping in a heavy duty foam insulation before it is buried and then continue the foam out through the floor.

Yes PEX pipe can be installed under a concrete slabPEX pipe can also be encased within a slab which is commonly used for radiant floor heating. Any water copper pipework to be burried in a concrete slab should always ve protected as to not react with the cement whilst it is going off. Grout sleeve with epoxy cement. This can be done by insulating the tube where it passes through the wall or by wrapping the tube with an approved tape to avoid abrasion and installing it through a sleeve. Correct pipeline protection slab design ensures that the slab effectively spans over the pipeline installation trench and transfers the imposed loads to the surrounding soils on either side of the pipe.

Source: pinterest.com

Source: pinterest.com

Any water copper pipework to be burried in a concrete slab should always ve protected as to not react with the cement whilst it is going off. The foam in a can is acidic will absorb moisture and is not resistant to UV. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators. If it is drainage then you may have to wrap black pipe wrap tape where it penetrates the concrete floor although you would be the first person I have heard of who had to do it. As well as correct pipeline protection slab design the correct pipe protection slab details must also be included in the design.

The normal practice that Im familiar with is to install the piping in a heavy duty foam insulation before it is buried and then continue the foam out through the floor. Im not convinced this is enough and so I was planning to ask he does the following 1. When the room was doubled in size a concrete slab floor was laid in the extension and the builders omitted to put extra heating in to accommodate for the larger room size. One of the pipes supply hot water and has a visible dent in it. You dont want the concrete touching the copper.

Source: johncflood.com

Source: johncflood.com

If it is drainage then you may have to wrap black pipe wrap tape where it penetrates the concrete floor although you would be the first person I have heard of who had to do it. According to petrographer Bernie Erlin copper wont corrode in concrete unless soluble chlorides are. Ive also been told to wrap protruding copper pipes with tar paper before embedding them in concrete. Correct pipeline protection slab design ensures that the slab effectively spans over the pipeline installation trench and transfers the imposed loads to the surrounding soils on either side of the pipe. Lance kirk FL worry more about the fill dirt surrouding the copper the use of the copper as the main electrical ground and controlling the incoming ph level if you can keep the concrete guys from kinking the copper after its installed your grand kids will still be well served by your copper system.

Source: pinterest.com

Source: pinterest.com

In cases where PEX pipe penetrates a concrete slab it must be protected with a nonmetallic sleeve at the penetration point. An expectation well supported by the excellent corrosion resistance of copper alloys used in these applications. How to repair copper pipes using a sleeve step 1. 15mm copper pipes will need to move as they expand contract with the heat produced. Break the slab cap them off under the slab and patch up the slab or 2.

Source: pinterest.com

Source: pinterest.com

I plan to angle grind a slot for 2 15mm copper pipes and I plan to bend the angles out of the slab and then refloat over the pipe. This is a thick viscous liquid that is blown through your copper water pipes. Thats the phrase that comes to mind for all who have installed copper and copper alloy piping systems in buried underground applications. For potable water pipes we generally use epoxy coatings. If you have foam pipe insulation you can use that instead of FG.

Source: axiumacademy.net

Source: axiumacademy.net

Then the concrete is poured and the foam also keeps the concrete from contacting the copper pipe. Break the slab cap them off under the slab and patch up the slab or 2. Please refer to your local plumbing code for specific requirements regarding the protection of pipes and tubes passing through concrete and masonry floors and walls. If you can find the point of entry and follow it to the meter use a placement for your sump pit far from this assumed line. Wrap hessian sleeving around all of the pipes ensuring theyre covered 2.

When the room was doubled in size a concrete slab floor was laid in the extension and the builders omitted to put extra heating in to accommodate for the larger room size. Wrap hessian sleeving around all of the pipes ensuring theyre covered 2. I plan to angle grind a slot for 2 15mm copper pipes and I plan to bend the angles out of the slab and then refloat over the pipe. Break the slab cap them off under the slab and patch up the slab or 2. Concrete in direct contact with copper would corrode it.

Break the slab cap them off under the slab and patch up the slab or 2. Im not convinced this is enough and so I was planning to ask he does the following 1. According to petrographer Bernie Erlin copper wont corrode in concrete unless soluble chlorides are. I know this sounds nuts but it helps spot the leak. Break the slab cap them off and put some sort of access box and cover or 3.

Source: youtube.com

Source: youtube.com

It will be very difficult to detect this line in concrete with rebar. In cases where PEX pipe penetrates a concrete slab it must be protected with a nonmetallic sleeve at the penetration point. In years gone by the material of choice would have been denzo tape but these days most engineers use insulation tape and pipe lagging with cable ties as this will protect the copped from being corroded by the cement. I dont know if he needs the pipes but if youre going to fill the hole and the pipes are penetrating through then what you do is you wrap it with a lot of duct tape I mean pretty thick about an eighth of an inch thick on duct tape and go ahead and pour the concrete. Then the concrete is poured and the foam also keeps the concrete from contacting the copper pipe.

Source: youtube.com

Source: youtube.com

You could accomplish the same things by placing a geotextile over the pipe and using a higher modulus material layer over the geotextile. If it is going through grade beams in the floor you have to wrap it with foam ribbon or rubber pipe insulation. Ive heard that copper pipes that penetrate concrete floors and copper shower pans in contact with concrete or cement board can corrode. As well as correct pipeline protection slab design the correct pipe protection slab details must also be included in the design. If it is drainage then you may have to wrap black pipe wrap tape where it penetrates the concrete floor although you would be the first person I have heard of who had to do it.

Source: refrigeration-engineer.com

Source: refrigeration-engineer.com

If you have foam pipe insulation you can use that instead of FG. Damned if you do Damned if you dont. The foam in a can is acidic will absorb moisture and is not resistant to UV. If you do not have soil between the pipe and slab bridging the slab will protect the top of the pipe but increase the lateral load on the pipe. Even if the pipe is fully encased in concrete it can still freeze due to the permafrost and low.

Source:

Source:

Think about using plastic push fit pipes instead Run them in a plastic waste pipe. Think about using plastic push fit pipes instead Run them in a plastic waste pipe. Im not convinced this is enough and so I was planning to ask he does the following 1. The normal practice that Im familiar with is to install the piping in a heavy duty foam insulation before it is buried and then continue the foam out through the floor. Correct pipeline protection slab design ensures that the slab effectively spans over the pipeline installation trench and transfers the imposed loads to the surrounding soils on either side of the pipe.

You could accomplish the same things by placing a geotextile over the pipe and using a higher modulus material layer over the geotextile. Thats the phrase that comes to mind for all who have installed copper and copper alloy piping systems in buried underground applications. Sleeving copper under a slab. One of the pipes supply hot water and has a visible dent in it. I know this sounds nuts but it helps spot the leak.

Source: farmihomie.com

Source: farmihomie.com

An expectation well supported by the excellent corrosion resistance of copper alloys used in these applications. Ive heard that copper pipes that penetrate concrete floors and copper shower pans in contact with concrete or cement board can corrode. The foam in a can is acidic will absorb moisture and is not resistant to UV. How to repair copper pipes using a sleeve step 1. If you can find the point of entry and follow it to the meter use a placement for your sump pit far from this assumed line.

Source: nuflowmidwest.com

Source: nuflowmidwest.com

You dont want the concrete touching the copper. Sleeving copper under a slab. Caulk both sides and not too thick. This can be done by insulating the tube where it passes through the wall or by wrapping the tube with an approved tape to avoid abrasion and installing it through a sleeve. Break the slab cap them off and put some sort of access box and cover or 3.

Source: pinterest.com

Source: pinterest.com

Stuff fiberglass in the void and caulk with Neutral cure Silicone sealant tool concave with spatula. How to repair copper pipes using a sleeve step 1. This can be done by insulating the tube where it passes through the wall or by wrapping the tube with an approved tape to avoid abrasion and installing it through a sleeve. One of the pipes supply hot water and has a visible dent in it. I plan to angle grind a slot for 2 15mm copper pipes and I plan to bend the angles out of the slab and then refloat over the pipe.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title how to protect copper pipe in concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.