Your How to put control joints in concrete images are ready in this website. How to put control joints in concrete are a topic that is being searched for and liked by netizens today. You can Find and Download the How to put control joints in concrete files here. Get all free images.

If you’re looking for how to put control joints in concrete pictures information linked to the how to put control joints in concrete interest, you have come to the right blog. Our site always gives you hints for downloading the highest quality video and image content, please kindly surf and locate more informative video articles and graphics that fit your interests.

How To Put Control Joints In Concrete. Tooled joints should be re-established with each. When control joints are required concrete masonry only requires vertical control joints. Shrinkage control joints or between shrinkage control joints and a free joint should be between 21 and 11 so no bay should be more that 6 6 m. Concrete needs to be able to freely shrink as it dries or to expand and contract with temperature changes to help minimize any random cracking.

Well Placed Joints In Concrete Help Channel Cracking Concrete Decor From concretedecor.net

Well Placed Joints In Concrete Help Channel Cracking Concrete Decor From concretedecor.net

It will also save you a lot of strain time and money. Ive installed thousands of lineal feet of control joints in my. Therefore the timing of saw cuts is critical. Wear safety goggles and. For example a 6 slab would have cuts 12 18. For more information on Robo Joiner a.

If a slab such as a driveway is partially hardened and has no concrete control joints you can put them in with a cement saw.

Third all panels created by contraction joints should be as square as possible. Control joints manage the inevitable and unsightly cracking that appears in a concrete slab often soon after it is poured. Therefore the timing of saw cuts is critical. Based on this we would recommend that you put a joint dividing each poured section in two in each direction creating 9x75-foot panels. Third all panels created by contraction joints should be as square as possible. This will also work on hardened concrete.

Source: buyersask.com

Source: buyersask.com

Note that it should only be used where no other type of concrete control joints have been installed in the concrete. The cuts should be made at a predetermined spacing and only after the concrete has obtained sufficient strength but before internal cracking begins. Control joints are a brilliantly simple way to control cracking in curing concrete. According to the U. Laying flooring over top.

Source: buyersask.com

Source: buyersask.com

While experience will help you get a better idea of what works for your concrete and climate there is a rule of thumb to start with. It will also save you a lot of strain time and money. Knowing when to cut control joints in concrete is an important step when pouring a fresh concrete slab. Joints may be tooled into the surface first pass prior to the onset of bleeding or immediately with the first pass of the floating operation. Normally joint reinforcement is used in the common joint between the two to distribute the.

Source: blog.strongholdfloors.com

Source: blog.strongholdfloors.com

Concrete needs to be able to freely shrink as it dries or to expand and contract with temperature changes to help minimize any random cracking. Third all panels created by contraction joints should be as square as possible. If a slab such as a driveway is partially hardened and has no concrete control joints you can put them in with a cement saw. Properly placed control joints will allow concrete to shrink expand and contract reducing the tendency for it to crack. If a slab is 4 inches thick control joints should be placed on an 8-foot grid.

Source: diy.stackexchange.com

Source: diy.stackexchange.com

Supplementary steel may be placed in irregularly shaped concrete floor slabs in positions shown in NZS 36042011 Figure 718 but must not be installed across shrinkage control joints. Ive been in the concrete floor business for over 30 years. Concrete needs to be able to freely shrink as it dries or to expand and contract with temperature changes to help minimize any random cracking. According to the U. For more information on Robo Joiner a.

Source: forum.nachi.org

Source: forum.nachi.org

Fibers will not have any effect on the spacing of control joints but will help to reduce plastic shrinkage cracking. Properly placed control joints will allow concrete to shrink expand and contract reducing the tendency for it to crack. The longer the first pass for jointing is delayed the more difficult it will be to shape clean straight line joints. 2-3 times the thickness of your slab in feet. Normally joint reinforcement is used in the common joint between the two to distribute the.

Source: concretedecor.net

Source: concretedecor.net

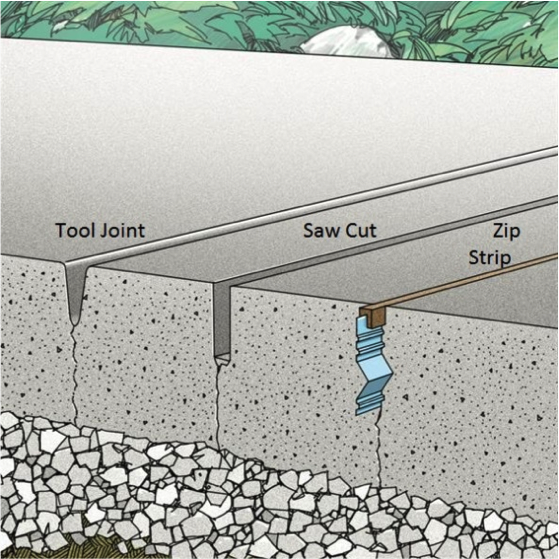

When control joints are required concrete masonry only requires vertical control joints. Harder than rocket science. This groove needless to say is called a control. Second the minimum depth of a joint should be a fourth of the thickness of the concrete. Supplementary steel may be placed in irregularly shaped concrete floor slabs in positions shown in NZS 36042011 Figure 718 but must not be installed across shrinkage control joints.

Source: mastercutconcrete.com.au

Source: mastercutconcrete.com.au

Federal Highway Administration a sufficiently deep groove weakens a concrete slab along that joint and encourages cracks to develop in and underneath it instead of elsewhere on the slab. Recap On Cutting Concrete Control Joints Control Joints are not intended to stop cracking but rather control cracking It is best to cut joints as early as possible either while finishing with a concrete groover or within 6-18 hours after. Joints may be tooled into the surface first pass prior to the onset of bleeding or immediately with the first pass of the floating operation. One of the first places to start is knowing how much space you need between your cuts. First maximum joint spacing should be 24 to 36 times the thickness of the slab with a maximum spacing of 15 feet.

Source: schedulefred.com

Source: schedulefred.com

While experience will help you get a better idea of what works for your concrete and climate there is a rule of thumb to start with. Control joints are a brilliantly simple way to control cracking in curing concrete. This will also work on hardened concrete. Third all panels created by contraction joints should be as square as possible. A control joint or contraction joint is intended to induce cracking in a concrete slab.

Source: jlconline.com

Source: jlconline.com

For more information on Robo Joiner a. Normally joint reinforcement is used in the common joint between the two to distribute the. One of the first places to start is knowing how much space you need between your cuts. Recap On Cutting Concrete Control Joints Control Joints are not intended to stop cracking but rather control cracking It is best to cut joints as early as possible either while finishing with a concrete groover or within 6-18 hours after. Supplementary steel may be placed in irregularly shaped concrete floor slabs in positions shown in NZS 36042011 Figure 718 but must not be installed across shrinkage control joints.

Source: buyersask.com

Source: buyersask.com

Based on this we would recommend that you put a joint dividing each poured section in two in each direction creating 9x75-foot panels. Shrinkage control joints or between shrinkage control joints and a free joint should be between 21 and 11 so no bay should be more that 6 6 m. Therefore the timing of saw cuts is critical. Third all panels created by contraction joints should be as square as possible. Control joints are a brilliantly simple way to control cracking in curing concrete.

Source: schedulefred.com

Source: schedulefred.com

Saw cuts are a used to create control joints in concrete which help control where cracking occurs due to shrinkage. Fibers will not have any effect on the spacing of control joints but will help to reduce plastic shrinkage cracking. Shrinkage control joints or between shrinkage control joints and a free joint should be between 21 and 11 so no bay should be more that 6 6 m. Third all panels created by contraction joints should be as square as possible. Think of it as a planned crack.

Source: buyersask.com

Source: buyersask.com

Laying flooring over top. When materials with different movement properties such as concrete masonry and clay masonry are used in the same wythe the movement difference needs to be accounted for in the design. Tooled joints should be re-established with each. Wear safety goggles and. The length width ratio of concrete panels should not exceed 15 to 1.

Source: howtobuildahouseblog.com

Source: howtobuildahouseblog.com

Based on this we would recommend that you put a joint dividing each poured section in two in each direction creating 9x75-foot panels. In this article we explain what control joint cutting is how it is different from expansion joint cutting and how and when you need to get a control. 2-3 times the thickness of your slab in feet. Supplementary steel may be placed in irregularly shaped concrete floor slabs in positions shown in NZS 36042011 Figure 718 but must not be installed across shrinkage control joints. If a slab is 4 inches thick control joints should be placed on an 8-foot grid.

Source: wrmeadows.com

Source: wrmeadows.com

First maximum joint spacing should be 24 to 36 times the thickness of the slab with a maximum spacing of 15 feet. First maximum joint spacing should be 24 to 36 times the thickness of the slab with a maximum spacing of 15 feet. While experience will help you get a better idea of what works for your concrete and climate there is a rule of thumb to start with. In this article we explain what control joint cutting is how it is different from expansion joint cutting and how and when you need to get a control. Ive been in the concrete floor business for over 30 years.

Source: youtube.com

Source: youtube.com

The length width ratio of concrete panels should not exceed 15 to 1. For more info on this check ACI 302 ACI 360 or Designing Floor Slabs on Grade by Boyd. Control joints are a brilliantly simple way to control cracking in curing concrete. Cuts should be approx. In this article we explain what control joint cutting is how it is different from expansion joint cutting and how and when you need to get a control.

Source: youtube.com

Source: youtube.com

Fibers will not have any effect on the spacing of control joints but will help to reduce plastic shrinkage cracking. A joint cut into a slab to ensure that as the concrete slab. Second the minimum depth of a joint should be a fourth of the thickness of the concrete. The longer the first pass for jointing is delayed the more difficult it will be to shape clean straight line joints. Knowing when to cut control joints in concrete is an important step when pouring a fresh concrete slab.

Source: youtube.com

Source: youtube.com

Recap On Cutting Concrete Control Joints Control Joints are not intended to stop cracking but rather control cracking It is best to cut joints as early as possible either while finishing with a concrete groover or within 6-18 hours after. To avoid shrinkage cracks control joints are placed according to accepted formulas based on the thickness of concrete and the configuration of the forms. Joints may be tooled into the surface first pass prior to the onset of bleeding or immediately with the first pass of the floating operation. Harder than rocket science. When control joints are required concrete masonry only requires vertical control joints.

Source: builderbill-diy-help.com

Source: builderbill-diy-help.com

For example a 6 slab would have cuts 12 18. The length width ratio of concrete panels should not exceed 15 to 1. This will also work on hardened concrete. According to the U. Think of it as a planned crack.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site beneficial, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to put control joints in concrete by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.