Your Manufacturing process of concrete pdf images are ready. Manufacturing process of concrete pdf are a topic that is being searched for and liked by netizens today. You can Download the Manufacturing process of concrete pdf files here. Get all royalty-free photos and vectors.

If you’re looking for manufacturing process of concrete pdf images information connected with to the manufacturing process of concrete pdf interest, you have pay a visit to the right site. Our website frequently gives you suggestions for seeing the maximum quality video and picture content, please kindly search and locate more informative video articles and graphics that fit your interests.

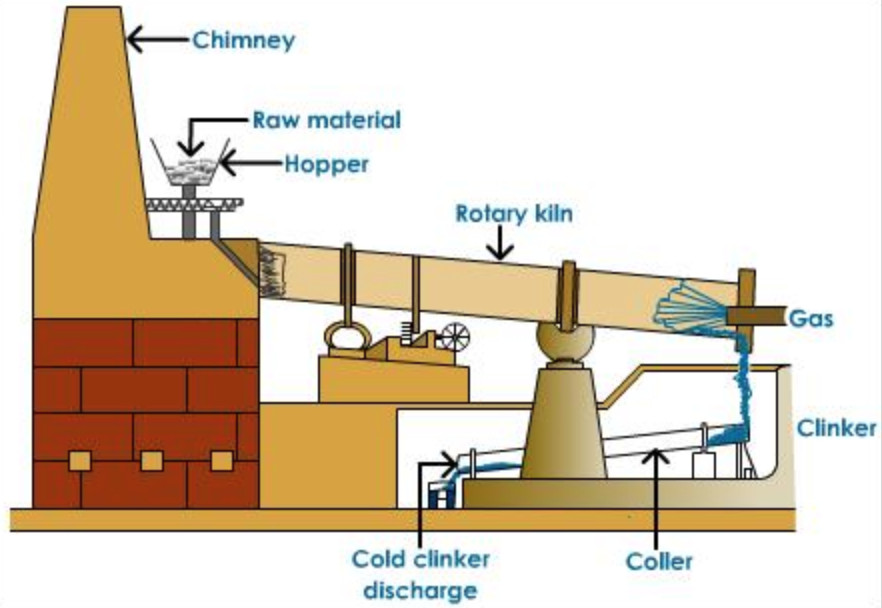

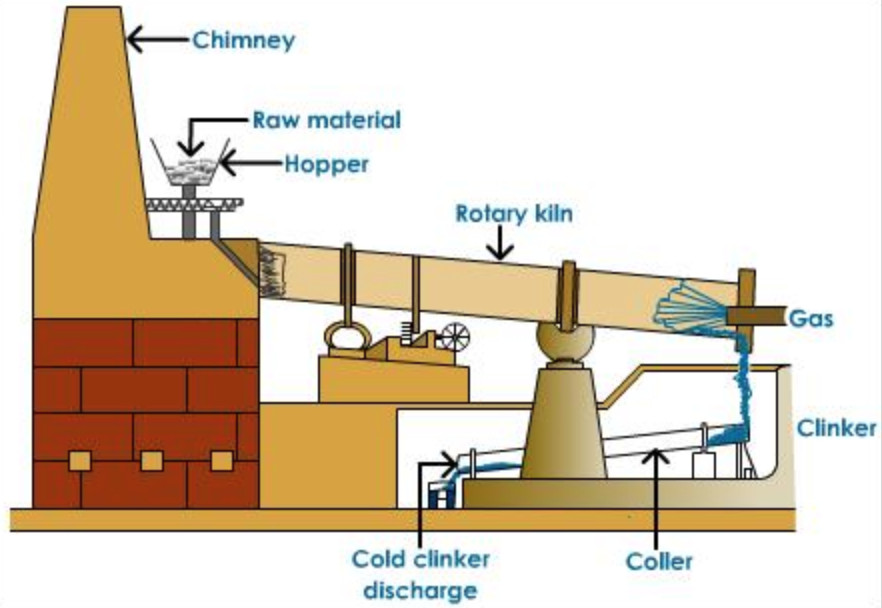

Manufacturing Process Of Concrete Pdf. The various stages of manufacture of concrete are. Ready-mix concrete is normally delivered in two ways. 2- Dry process ___ grinding and mixing of the raw materials in their dry. First is the barrel truck or intransit mixers.

Cement Chemistry Class 11 S Block Elements From classnotes.org.in

Cement Chemistry Class 11 S Block Elements From classnotes.org.in

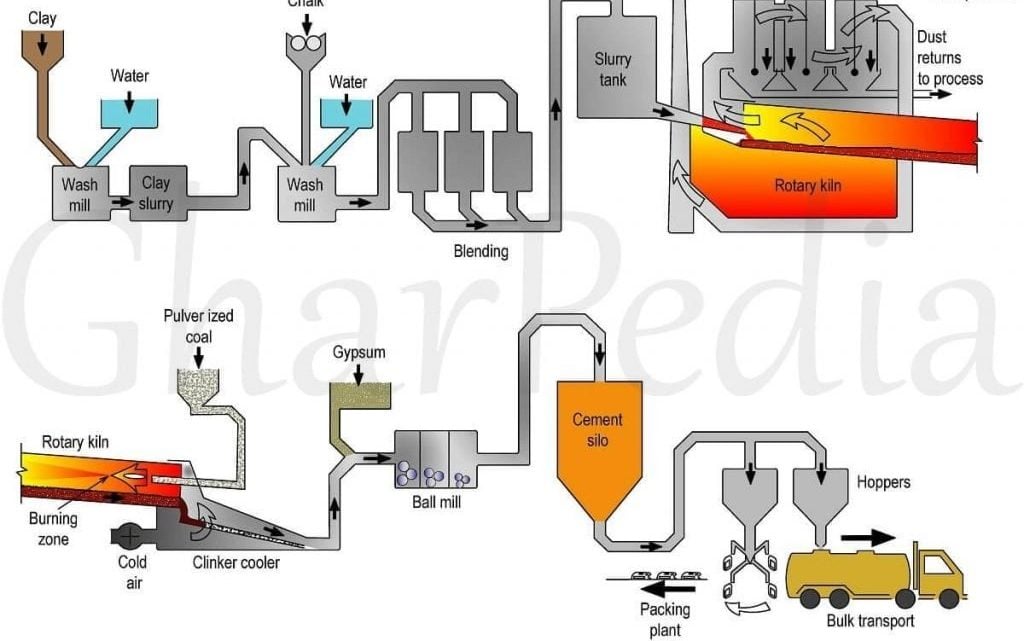

2- Dry process ___ grinding and mixing of the raw materials in their dry. First is the barrel truck or intransit mixers. It can be manufac-tured by any of. The experience of manufacturing the precast concrete insulated panels for the concrete house is presented here as a case study of full-scale production in a plant. This requires some rules to be followed in the various stages of concrete production. Methods of cement manufacturing 1- Wet process ___ grinding and mixing of the raw materials in the existence of water.

Ready mixed concrete is proportioned and mixed off the project site and is delivered to the construction area in a freshly mixed and unhardened state.

Its use in day-to-day plant operations enables management and production personnel to understand the requirements for manufacturing quality precast. The experience of manufacturing the precast concrete insulated panels for the concrete house is presented here as a case study of full-scale production in a plant. Methods of cement manufacturing 1- Wet process ___ grinding and mixing of the raw materials in the existence of water. The process of manufacture of cement concrete hollow blocks involves the Following 5 stages. 2- Dry process ___ grinding and mixing of the raw materials in their dry. Modern concrete is made by mixing aggregate sand stones and shingle with Portland cement and water and allowing it to set.

Source: brainkart.com

Source: brainkart.com

Methods of cement manufacturing 1- Wet process ___ grinding and mixing of the raw materials in the existence of water. Ready mixed concrete is proportioned and mixed off the project site and is delivered to the construction area in a freshly mixed and unhardened state. Portland cement is the basic ingredient of concrete. The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes as can be. Ready-mix concrete RMC is a type of concrete which is manufactured in a cement factory or specifically known as the batching plant according to a given set of proportions and then.

Source: researchgate.net

Source: researchgate.net

Download full-text PDF Read full. The Potential of Laterite as Fine Aggregate in Foamed. Download full-text PDF Read full. There is no constraint in the availability of cement main raw materials with the exception of some. The concrete mixes transports and.

Source: greenspec.co.uk

Source: greenspec.co.uk

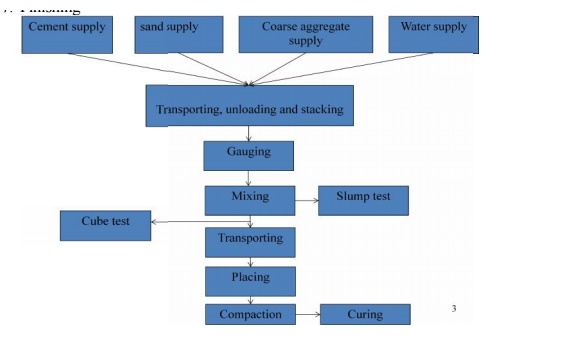

This study deals with the manufacturing process of the autoclaved aerated concrete blocks. Methods of cement manufacturing 1- Wet process ___ grinding and mixing of the raw materials in the existence of water. The process of manufacture of cement concrete hollow blocks involves the Following 5 stages. The cement industry planning process is centralized and optimization oriented. A Batching b Mixing c Transporting d Placing e Compacting f Curing g Finishing.

The aim of quality control is to ensure the production of con crete of uniform strength from batch to batch. The cement industry planning process is centralized and optimization oriented. The concrete mixes transports and. Ready-mix concrete RMC is a type of concrete which is manufactured in a cement factory or specifically known as the batching plant according to a given set of proportions and then. First a description of the.

Source: sciencedirect.com

Source: sciencedirect.com

1 Proportioning 2 Mixing 3 Compacting 4 Curing 5 Drying 1 Proportioning. Mechanical properties and testing of hardened concrete. Of these ingredients the most important is Portland cement. Its use in day-to-day plant operations enables management and production personnel to understand the requirements for manufacturing quality precast. The Potential of Laterite as Fine Aggregate in Foamed.

Source: link.springer.com

Source: link.springer.com

1 Proportioning 2 Mixing 3 Compacting 4 Curing 5 Drying 1 Proportioning. A Batching b Mixing c Transporting d Placing e Compacting f Curing g Finishing. The Concrete mix for delivery from a plant instead of mixing on the job site. Of these ingredients the most important is Portland cement. First is the barrel truck or intransit mixers.

Source: theengineeringcommunity.org

Source: theengineeringcommunity.org

A Batching b Mixing c Transporting d Placing e Compacting f Curing g Finishing. The various stages of manufacture of concrete are. The aim of quality control is to ensure the production of con crete of uniform strength from batch to batch. The Potential of Laterite as Fine Aggregate in Foamed. The cement industry planning process is centralized and optimization oriented.

Source: classnotes.org.in

Source: classnotes.org.in

This type of truck delivers concrete in a plastic state to the site. Methods of Mixing. This type of truck delivers concrete in a plastic state to the site. Ready-mix concrete RMC is a type of concrete which is manufactured in a cement factory or specifically known as the batching plant according to a given set of proportions and then. Manufacturing composition hydration properties and testing.

Source: sciencedirect.com

Source: sciencedirect.com

This study deals with the manufacturing process of the autoclaved aerated concrete blocks. Mechanical properties and testing of hardened concrete. Portland cement is the basic ingredient of concrete. The book is intended for engineers of any specialization to present an overview of manufacturing process and the material used in it. First a description of the.

Source: sciencedirect.com

Source: sciencedirect.com

Portland cement is the basic ingredient of concrete. It can be manufac-tured by any of. This type of truck delivers concrete in a plastic state to the site. Methods of Mixing. Concrete is casting into mould therefore the fresh concrete will be used to determine the workability of concrete mix and after the concrete harden strength test will be measure on 7.

Source: britannica.com

Source: britannica.com

Concrete Manufacturing Process consists of many stages. Concrete is casting into mould therefore the fresh concrete will be used to determine the workability of concrete mix and after the concrete harden strength test will be measure on 7. This requires some rules to be followed in the various stages of concrete production. This study deals with the manufacturing process of the autoclaved aerated concrete blocks. 1Hands using hand shovels.

Source: cementplantequipment.com

Source: cementplantequipment.com

A Batching b Mixing c Transporting d Placing e Compacting f Curing g Finishing. This study deals with the manufacturing process of the autoclaved aerated concrete blocks. 2- Dry process ___ grinding and mixing of the raw materials in their dry. A Batching b Mixing c Transporting d Placing e Compacting f Curing g Finishing. The process of manufacture of cement concrete hollow blocks involves the Following 5 stages.

Source: gharpedia.com

Source: gharpedia.com

Concrete Manufacturing Process consists of many stages. 2- Dry process ___ grinding and mixing of the raw materials in their dry. The book is intended for engineers of any specialization to present an overview of manufacturing process and the material used in it. The aim of quality control is to ensure the production of con crete of uniform strength from batch to batch. The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes as can be.

Manufacturing composition hydration properties and testing. The book is intended for engineers of any specialization to present an overview of manufacturing process and the material used in it. This requires some rules to be followed in the various stages of concrete production. First a description of the. 1 Proportioning 2 Mixing 3 Compacting 4 Curing 5 Drying 1 Proportioning.

Source: pinterest.com

Source: pinterest.com

Ready-mix concrete RMC is a type of concrete which is manufactured in a cement factory or specifically known as the batching plant according to a given set of proportions and then. Its use in day-to-day plant operations enables management and production personnel to understand the requirements for manufacturing quality precast. Mechanical properties and testing of hardened concrete. This requires some rules to be followed in the various stages of concrete production. Of these ingredients the most important is Portland cement.

Source: sciencedirect.com

Source: sciencedirect.com

Manufacturing composition hydration properties and testing. Of these ingredients the most important is Portland cement. The experience of manufacturing the precast concrete insulated panels for the concrete house is presented here as a case study of full-scale production in a plant. Methods of Mixing. It can be manufac-tured by any of.

Source: civilblog.org

Source: civilblog.org

It can be manufac-tured by any of. Manufacturing composition hydration properties and testing. The book is intended for engineers of any specialization to present an overview of manufacturing process and the material used in it. First a description of the. The concrete mixes transports and.

![]() Source: cementequipment.org

Source: cementequipment.org

Its use in day-to-day plant operations enables management and production personnel to understand the requirements for manufacturing quality precast. The concrete mixes transports and. The various stages of manufacture of concrete are. The book is intended for engineers of any specialization to present an overview of manufacturing process and the material used in it. Manufacturing composition hydration properties and testing.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title manufacturing process of concrete pdf by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.