Your Power floated concrete floor specification images are ready. Power floated concrete floor specification are a topic that is being searched for and liked by netizens now. You can Find and Download the Power floated concrete floor specification files here. Download all free photos.

If you’re searching for power floated concrete floor specification pictures information connected with to the power floated concrete floor specification topic, you have pay a visit to the right site. Our website always gives you hints for downloading the maximum quality video and picture content, please kindly search and locate more informative video content and images that match your interests.

Power Floated Concrete Floor Specification. Power floated concrete 63 Dry I 61 Dusty Dusty Dusty I II III 47 41 46 Wet I 21 Wet II 29 Wet III 24 Installed cement 137 Damp I 40 paver Wet I 26 Power floated concrete with hardener 168 Dry Dry Dry I II III 50 49 45 Greasy difficult to get totally clean Wet I 19 Wet II 25 Wet III 21 Power floated concrete worn. This is a 100 solid color epoxy with a urethane coating that will match the existing base color. Power floats have an electric motor or petrol engine fixed over a circular pan or skimmer which. Or a troweling exhibit a definite polished sheen.

Power Floated Concrete Floors Screed Floors From screedfloor.co.uk

Power Floated Concrete Floors Screed Floors From screedfloor.co.uk

It is the General Contractors GC responsibility to insure all. Float and Trowel Finishes. Use this Specification Guide in conjunction with the individual Cementaid product Data Sheets to specify your enhanced property industrial concrete floors. By clipping float blades or pans to your power. This produced a flattish slightly textured surface which often contained float marks. Power-floating produces a flat smooth dense finish.

The pans can greatly increase flatness.

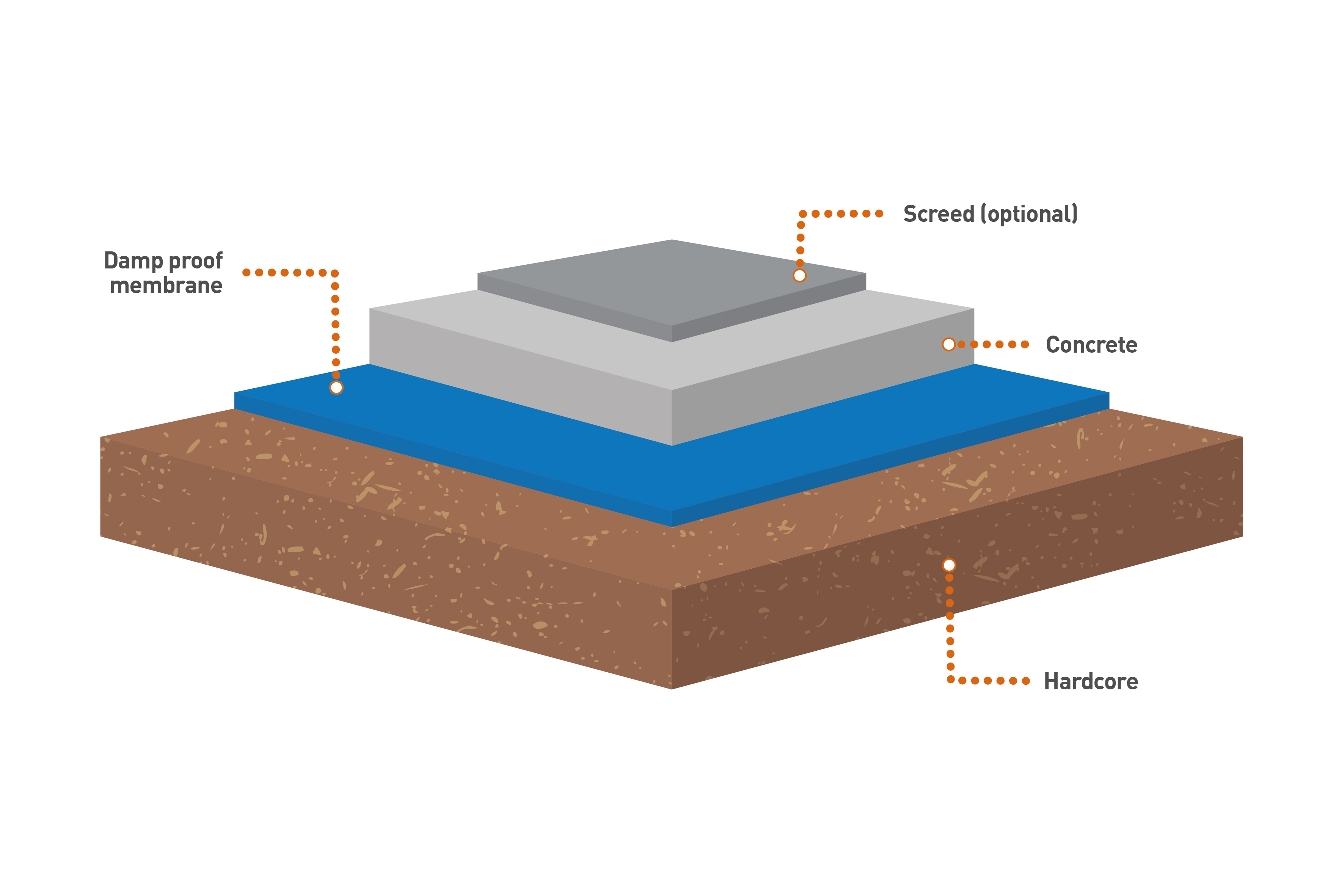

For many internal ground floors the most suitable tolerances to be worked to are free movement classifications FM as defined in TR34 by The Concrete SocietyA floor is classified as free movement if it can be driven around freely by vehicles such as forklifts without too many obstacles such as columns or walls. Power floated concrete floors are extremely hard wearing and require no further finish but a range of polishes resins and screeds can be applied to have your floors looking at their very best. To prevent corrosion or dampness then you can also eliminate all expansion joints and saw cuts too. This is a 100 solid color epoxy with a urethane coating that will match the existing base color. Poured and allowed to partially set. Power floats have an electric motor or petrol engine fixed over a circular pan or skimmer which.

Source: concretefloorpolisher.co.uk

Source: concretefloorpolisher.co.uk

Protection of concrete work. Elimination of the use of power-floated concrete on site The superior self-compacting concrete QUALITY SURFACE FINISH Agilia Horizontals finishing characteristics and high quality surface finish often mean the elimination of the use of power-floated concrete on site. The flooring also takes only 24 hours to dry before it is suitable for foot traffic again. Isomat dry system floating floors can still provide a high degree of noise and vibration isolation. Question now is what do we do with it or what do we get the quarry to do with it.

Source: screedfloor.co.uk

Source: screedfloor.co.uk

Question now is what do we do with it or what do we get the quarry to do with it. Our Resinous 123 Floor System is a fabulous option when you have large areas you want to coat with a seamless chemical UV and scratch resistant clean floor look. It is the General Contractors GC responsibility to insure all. Floor finish tolerance to BS 8204 -1 SR2. Concrete shall be floated as soon as sound.

Source: pinterest.com

Source: pinterest.com

I thought it was too early and he would have been there to 1900 at least. Use this Specification Guide in conjunction with the individual Cementaid product Data Sheets to specify your enhanced property industrial concrete floors. A power float is a hand-operated machine used to produce a smooth dense and level surface finish to insitu concrete beds. Our Resinous 123 Floor System is a fabulous option when you have large areas you want to coat with a seamless chemical UV and scratch resistant clean floor look. A power float is a machine used by hand either with the operator walking behind it or riding on a larger one if the project requires it in order to produce a smooth dense and level finish to a newly-laid onsite poured concrete floor.

Source: industrialconcreteflooring.co.uk

Source: industrialconcreteflooring.co.uk

I thought it was too early and he would have been there to 1900 at least. Nowadays the operation is carried. Power floated concrete floors are extremely hard wearing and require no further finish but a range of polishes resins and screeds can be applied to have your floors looking at their very best. The trowel shall be applied with considerable pressure and when completed the surface of Types 1 5 water sheen disappears and when it will support the and 6 finishes shall be free of chatter marks and shall weight of a man and a power float. For achieving maximum performance in power floated concrete.

Source: forum.buildhub.org.uk

Source: forum.buildhub.org.uk

Create a floating slab with concrete or screed or where build-up heights are constrained. Question now is what do we do with it or what do we get the quarry to do with it. Here are 5 reasons to choose power float concrete flooring. A power float is a hand-operated machine used to produce a smooth dense and level surface finish to insitu concrete beds. Avoid Premature Finishing.

Source: concreteconstruction.net

Source: concreteconstruction.net

Power floated concrete floors are extremely hard wearing and require no further finish but a range of polishes resins and screeds can be applied to have your floors looking at their very best. Question now is what do we do with it or what do we get the quarry to do with it. This is a 100 solid color epoxy with a urethane coating that will match the existing base color. A Powerfloat finish machine sits on top of the concrete in a similar manner to a hovercraft with a series of blades underneath which rotate at a very high speed. It is also the ideal solution in areas where there is heavy traffic.

Source: becosan.com

Source: becosan.com

Power float was in the van and up the road just after 1730. A power float is a hand-operated machine used to produce a smooth dense and level surface finish to insitu concrete beds. Our Resinous 123 Floor System is a fabulous option when you have large areas you want to coat with a seamless chemical UV and scratch resistant clean floor look. This produced a flattish slightly textured surface which often contained float marks. Floated with a power trowel.

Source: theconstructor.org

Source: theconstructor.org

Power-floating produces a flat smooth dense finish. For many internal ground floors the most suitable tolerances to be worked to are free movement classifications FM as defined in TR34 by The Concrete SocietyA floor is classified as free movement if it can be driven around freely by vehicles such as forklifts without too many obstacles such as columns or walls. Concrete was in yesterday and levelled by shortly after 9. Power floats have an electric motor or petrol engine fixed over a circular pan or skimmer which. Power-floated concrete floors are a great alternative to choosing resins or floor paints.

Source: researchgate.net

Source: researchgate.net

This can be finished with a clear urethane top coat. The trowel shall be applied with considerable pressure and when completed the surface of Types 1 5 water sheen disappears and when it will support the and 6 finishes shall be free of chatter marks and shall weight of a man and a power float. Wait to start power floating until the bleed water sheen has disappeared and the concrete has stiffened sufficiently to support a. When walking on the partially set slab footprint indents should be between 3 5mm deep and concrete shouldnt stick to your boots. Power float was in the van and up the road just after 1730.

Source: researchgate.net

Source: researchgate.net

It is also the ideal solution in areas where there is heavy traffic. The use of power float machinery results in a smooth finish that is incredibly easy to maintain. Create a floating slab with concrete or screed or where build-up heights are constrained. I thought it was too early and he would have been there to 1900 at least. This can be finished with a clear urethane top coat.

Source: industrialconcreteflooring.co.uk

Source: industrialconcreteflooring.co.uk

Power floated concrete floors are extremely hard wearing and require no further finish but a range of polishes resins and screeds can be applied to have your floors looking at their very best. Here are 5 reasons to choose power float concrete flooring. This produced a flattish slightly textured surface which often contained float marks. Power-floated concrete is less prone to cracking and is also water and shock proof. Poured and allowed to partially set.

Source: helixsteel.com

Source: helixsteel.com

The thickness of the concrete. Floated with a power trowel. The trowel shall be applied with considerable pressure and when completed the surface of Types 1 5 water sheen disappears and when it will support the and 6 finishes shall be free of chatter marks and shall weight of a man and a power float. Areas within 15 meters of walls columns or. The floor is often restraightened several times prior to and after power floating.

Source: forum.buildhub.org.uk

Source: forum.buildhub.org.uk

A Powerfloat finish machine sits on top of the concrete in a similar manner to a hovercraft with a series of blades underneath which rotate at a very high speed. A power float is a hand-operated machine used to produce a smooth dense and level surface finish to insitu concrete beds. Power float concrete is a polished concrete finish with a range of both aesthetic and practical benefits for a range of sectors from industrial to residential. Floor finish tolerance to BS 8204 -1 SR2. At CFS we usually perform this task after your purchased concrete has partially set and has been leveled.

Source: pinterest.com

Source: pinterest.com

The thickness of the concrete. Power float concrete is a polished concrete finish with a range of both aesthetic and practical benefits for a range of sectors from industrial to residential. Buffing the surface of a freshly laid concrete floor will create a smooth surface with a high gloss shine. Here are 5 reasons to choose power float concrete flooring. Power floated concrete 63 Dry I 61 Dusty Dusty Dusty I II III 47 41 46 Wet I 21 Wet II 29 Wet III 24 Installed cement 137 Damp I 40 paver Wet I 26 Power floated concrete with hardener 168 Dry Dry Dry I II III 50 49 45 Greasy difficult to get totally clean Wet I 19 Wet II 25 Wet III 21 Power floated concrete worn.

Source: en.wikipedia.org

Source: en.wikipedia.org

The floor is often restraightened several times prior to and after power floating. Isomat dry system floating floors can still provide a high degree of noise and vibration isolation. Power floating a concrete slab is a process where the concrete slab is. Protection of concrete work. Nowadays the operation is carried.

Source: easymixconcrete.com

Source: easymixconcrete.com

Wait to start power floating until the bleed water sheen has disappeared and the concrete has stiffened sufficiently to support a. Power-floating produces a flat smooth dense finish. The use of power float machinery results in a smooth finish that is incredibly easy to maintain. At CFS we usually perform this task after your purchased concrete has partially set and has been leveled. Wait to start power floating until the bleed water sheen has disappeared and the concrete has stiffened sufficiently to support a.

Source: concretefloorpolisher.co.uk

Source: concretefloorpolisher.co.uk

At CFS we usually perform this task after your purchased concrete has partially set and has been leveled. At CFS we usually perform this task after your purchased concrete has partially set and has been leveled. The blades spin and polish out all imperfections to achieve a smooth and shiny finish. The use of power float machinery results in a smooth finish that is incredibly easy to maintain. Power floating a concrete slab is a process where the concrete slab is.

Source: concretefloorpolisher.co.uk

Source: concretefloorpolisher.co.uk

The blades spin and polish out all imperfections to achieve a smooth and shiny finish. Concrete shall be floated as soon as sound. The trowel shall be applied with considerable pressure and when completed the surface of Types 1 5 water sheen disappears and when it will support the and 6 finishes shall be free of chatter marks and shall weight of a man and a power float. And remember if you are using Everdure Caltite System ingredients for your floor eg. Nowadays the operation is carried.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title power floated concrete floor specification by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.