Your Precast concrete slab method statement images are available. Precast concrete slab method statement are a topic that is being searched for and liked by netizens now. You can Get the Precast concrete slab method statement files here. Get all free photos and vectors.

If you’re searching for precast concrete slab method statement images information linked to the precast concrete slab method statement topic, you have visit the right blog. Our site frequently provides you with suggestions for viewing the maximum quality video and picture content, please kindly hunt and locate more enlightening video content and images that match your interests.

Precast Concrete Slab Method Statement. Bangunan Masjid Quantity a PRECAST CONCRETE PILES 250mm x. Corners of the footing shall be marked on the blinding. The safe installation of precast concrete flooring and associated components CONTENTS See over for detailed contents 01 DEFINITIONS 1 02 BIBLIOGRAPHY 3 1 MANAGEMENT OF HEALTH AND SAFETY 5 2 SAFE WORKING METHOD STATEMENTS AND PRE-START CHECKS 13 3 TRAINING AND CERTIFICATION 17 4 DESIGN CONSIDERATIONS 19. The diagrams below illustrated the sequence of installation for the precast beam-slab system.

Pin On Armirovka Abalovka From pinterest.com

Pin On Armirovka Abalovka From pinterest.com

Activity A PILING WORK 1. They are trucked to the bridge construction site and lifted by cranes onto concrete or steel girders. 34 s H 1800 34H then H 530 feet The above example illustrates that precast concrete manhole. SAFETY ENVIRONMENTAL RISKS 21 HAZARD ANALYSIS RISK. The precast will be produced in xxxx precast factory located in xxxxx. The scope of this procedure covers the steps to be followed for the Fabrication and Installation of Precast Elements such as foundations columns beams staircases manholes and hollow-core slabs.

Name telephone number and email address.

The name contact details of the contractor. The safe installation of precast concrete flooring and associated components CONTENTS See over for detailed contents 01 DEFINITIONS 1 02 BIBLIOGRAPHY 3 1 MANAGEMENT OF HEALTH AND SAFETY 5 2 SAFE WORKING METHOD STATEMENTS AND PRE-START CHECKS 13 3 TRAINING AND CERTIFICATION 17 4 DESIGN CONSIDERATIONS 19. The erection sequence shall avoid multiple handling of elements. Using an allowable concrete stress of 45 of the minimum specified compressive strength of 4000 psi the allowable compressive stress would be 1800 psi. Slab may not have been removed prior to delivery. Name telephone number and email address.

Source: civilpaper.com

Source: civilpaper.com

This procedure is formed by the following method statements. 230 PRECAST CONCRETE 231 Precast concrete shall be cast where required by the relevant approved released for construction drawing. Method statement concrete support systems detailed safe work method statements about us method statement vnm sika com concrete slab construction swms bluesafe solutions method statement dubai methods of statement for precast deck slab installation method statement for erection and dismantling of slab formwork manual concrete rib construction method method. Lay concrete by pouring direct from a mixer spreading using shovels and compacting. 234 Precast concrete elements shall be stacked in such a way that no.

Source: pinterest.com

Source: pinterest.com

Secure 2x2 timber to the floor at wall edge to guide wall. It concerns all segment used for this project. They are trucked to the bridge construction site and lifted by cranes onto concrete or steel girders. Slab may not have been removed prior to delivery. Bangunan Masjid Quantity a PRECAST CONCRETE PILES 250mm x.

Source: bft-international.com

Source: bft-international.com

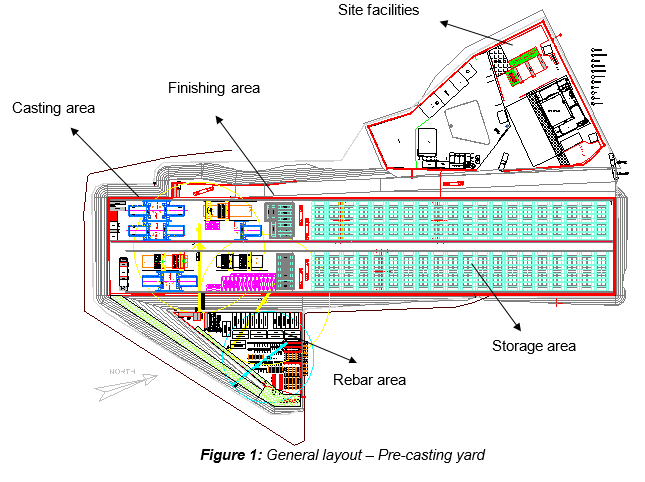

The erection sequence shall avoid multiple handling of elements. The name contact details of the contractor. The topping concrete and reinforcement provide a simple means of tying the floor and. Area used to manufacture and temporary store all precast segments. They are trucked to the bridge construction site and lifted by cranes onto concrete or steel girders.

View Method statement Machinerydocx from ME MISC at University of Technology Malaysia Johor Bahru Skudai. This Concrete Slab Method Statement template has been prepared and pre-completed for the construction and installation of a reinforced concrete slab. The diagrams below illustrated the sequence of installation for the precast beam-slab system. Project name and site address. Method statement for the installation of pre-stressed pre-cast concrete floor slabs Site details Contractor.

Source: pinterest.com

Source: pinterest.com

It concerns all segment used for this project. Substituting this value for s yields the following. 34 s H 1800 34H then H 530 feet The above example illustrates that precast concrete manhole. The Procedure Setting Out 1. View Method statement Machinerydocx from ME MISC at University of Technology Malaysia Johor Bahru Skudai.

Source: pinterest.com

Source: pinterest.com

34 s H 1800 34H then H 530 feet The above example illustrates that precast concrete manhole. Mark 100mm offset line from rear building edge. This procedure is formed by the following method statements. If required for final positioning crow bar will be used. Slab may not have been removed prior to delivery.

Source: pdfcoffee.com

Source: pdfcoffee.com

The main contractor to mark the coordinates along the length of the wall. Name telephone number and email address. Lay concrete using ready-mixed concrete poured from a mixer spread by hand full barrier PPE to be worn including gloves overalls and eye protection. Panels shall be erected on the footings and shall by supported by supporting jacks. Method Statement Curing of segments - HCMC-261-CSYD-CWS-MST-00021.

Source: qaqcconstruction.com

Source: qaqcconstruction.com

Slab may not have been removed prior to delivery. Slab may not have been removed prior to delivery. View Method statement Machinerydocx from ME MISC at University of Technology Malaysia Johor Bahru Skudai. Different composite slab thickness can be achieved as required by structural considerations by varying the topping thickness but keeping the precast thickness constant. The name contact details of the contractor.

Source: pinterest.com

Source: pinterest.com

Erection Sequence Precast concrete members shall be erected according to preplanned sequence. Precast pre-stressed concrete elements. Mark 100mm offset line from rear building edge. Bangunan Masjid Quantity a PRECAST CONCRETE PILES 250mm x. Surveyor to set cross reference.

Source: pinterest.com

Source: pinterest.com

Method statement for the installation of pre-stressed pre-cast concrete floor slabs Site details Contractor. Different composite slab thickness can be achieved as required by structural considerations by varying the topping thickness but keeping the precast thickness constant. Panels shall be erected on the footings and shall by supported by supporting jacks. Erection Sequence Precast concrete members shall be erected according to preplanned sequence. Lay concrete by pouring direct from a mixer spreading using shovels and compacting.

Source: in.pinterest.com

Source: in.pinterest.com

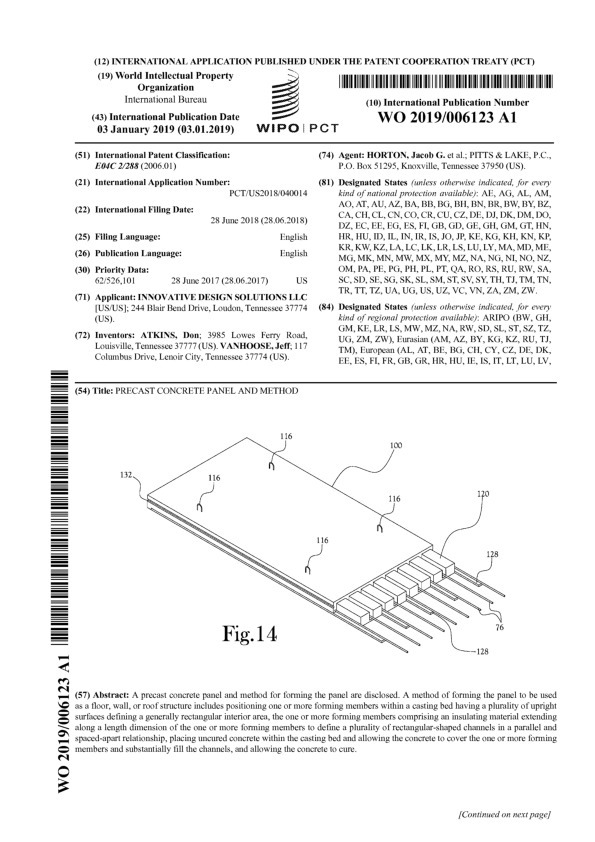

This will include form-work steel reinforcement work scaffolding propping back propping concreting works and removal of forms props scaffolding support. A precast concrete structural system should have strength and ductility capacity equivalent to that provided by a comparable monolithic reinforced concrete structure. Using an allowable concrete stress of 45 of the minimum specified compressive strength of 4000 psi the allowable compressive stress would be 1800 psi. Method Statement Curing of segments - HCMC-261-CSYD-CWS-MST-00021. Scope of Method Statement for Precast Concrete Fabrication and Installation.

Source: studylib.net

Source: studylib.net

Method statement concrete support systems detailed safe work method statements about us method statement vnm sika com concrete slab construction swms bluesafe solutions method statement dubai methods of statement for precast deck slab installation method statement for erection and dismantling of slab formwork manual concrete rib construction method method. The panels are usually precast at a manufacturing plant. Scope of Method Statement for Precast Concrete Fabrication and Installation. Ii Precast slabs shall be kept on top of the wooden battens and necessary side packing shall also be provided to avoid damages. 34 s H 1800 34H then H 530 feet The above example illustrates that precast concrete manhole.

Source: pinterest.com

Source: pinterest.com

Name telephone number and email address. Method Statement Precast segment production - Short Line Typical mould - HCMC-261-CSYD-CWS-MST-00041 All reference documents are intended to refer to the last issued revision. The erection plan is commonly prepared drawings If it is important for structural stability and for access to connections at specific location. Slab may not have been removed prior to delivery. A precast concrete structural system should have strength and ductility capacity equivalent to that provided by a comparable monolithic reinforced concrete structure.

Source: bft-international.com

Source: bft-international.com

The Procedure Setting Out 1. Activity A PILING WORK 1. The panels are usually precast at a manufacturing plant. 34 s H 1800 34H then H 530 feet The above example illustrates that precast concrete manhole. Offset wall position by 200 mm.

Source: in.pinterest.com

Source: in.pinterest.com

Panels shall be erected on the footings and shall by supported by supporting jacks. The purpose of this Method Statement is to establish the rules to be applied during all the. Ii Precast slabs shall be kept on top of the wooden battens and necessary side packing shall also be provided to avoid damages. Lay concrete using ready-mixed concrete poured from a mixer spread by hand full barrier PPE to be worn including gloves overalls and eye protection. Mark 100mm offset line from rear building edge.

Source: pinterest.com

Source: pinterest.com

34 s H 1800 34H then H 530 feet The above example illustrates that precast concrete manhole. Precast concrete section typically U-shaped consisting of a bottom slab two side webs and lateral top flanges. This Concrete Slab Method Statement template has been prepared and pre-completed for the construction and installation of a reinforced concrete slab. 232 Precast concrete elements will be constructed in the site 233 Precast concrete elements shall not be moved from the casting beds at least 48 hours after casting. The topping concrete and reinforcement provide a simple means of tying the floor and.

Source: researchgate.net

Source: researchgate.net

This will include form-work steel reinforcement work scaffolding propping back propping concreting works and removal of forms props scaffolding support. The safe installation of precast concrete flooring and associated components CONTENTS See over for detailed contents 01 DEFINITIONS 1 02 BIBLIOGRAPHY 3 1 MANAGEMENT OF HEALTH AND SAFETY 5 2 SAFE WORKING METHOD STATEMENTS AND PRE-START CHECKS 13 3 TRAINING AND CERTIFICATION 17 4 DESIGN CONSIDERATIONS 19. Panels shall be erected on the footings and shall by supported by supporting jacks. Using an allowable concrete stress of 45 of the minimum specified compressive strength of 4000 psi the allowable compressive stress would be 1800 psi. It concerns all segment used for this project.

Source: pinterest.com

Source: pinterest.com

Using an allowable concrete stress of 45 of the minimum specified compressive strength of 4000 psi the allowable compressive stress would be 1800 psi. 230 PRECAST CONCRETE 231 Precast concrete shall be cast where required by the relevant approved released for construction drawing. SAFETY ENVIRONMENTAL RISKS 21 HAZARD ANALYSIS RISK. Method Statement Precast segment production - Short Line Typical mould - HCMC-261-CSYD-CWS-MST-00041 All reference documents are intended to refer to the last issued revision. The main contractor to mark the coordinates along the length of the wall.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title precast concrete slab method statement by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.